Science: Chemistry:

Concept of Enzymatic Hydrogen Production by Light-Sensitized Anodized

Tubular TiO2 Photoanode

Dr.

Hyunku Joo and Jin-Wook Ha*

Korea

Institute of Energy Research,

*

Department of Energy and Environmental

ABSTRACT

In this article, different approach using a light-sensitized enzymatic(LSE) system has been proposed. The LSE is a way of producing hydrogen by coupling an inorganic

semiconductor with enzymes in a photoelectrochemical configuration. The system uses the intrinsic proton

reduction ability of hydrogenase enzyme in

tandem with an anodic compartment

where the electron donors like water undergo oxidative reaction on light-sensitized photoanode. Generated electrons are separated and moved

through an external circuit within a solar cell, which is applied for an

external bias, to the cathodic compartment and used for the reduction of proton

into hydrogen on the active sites of enzymes. Oxidized ions move to the

cathodic compartment through an ion bridge like nanofiltration(NF) membrane in

this study.

1.

INTRODUCTION

Environmental

remediation by photocatalysis has been an attractive issue over the last decade, while recently numerous studies have focused on hydrogen evolution from water as a clean energy

resource since the invention of photochemical water splitting over TiO2

electrode in 1972. However, the

photocatalytic process has been simultaneously criticized as being uneconomical

compared to other oxidative treatment systems and up-to-date hydrogen

production systems due to its inherently

low efficiency and limitations resulting from the necessity for a novel material, an appropriate light source and immobilization,

which may increase the

overall energy costs[1]. Therefore, research

attention has focused on developing economically feasible photocatalytic systems with future commercial

applications. Comprehensive

reviews on semiconductor particulate systems[2], on TiO2

photocatalyst[3] and on the material-related issues[4-5] for hydrogen

production were published. Compared with other photocatalysts, TiO2

is much more promising as it is stable, non-corrosive, environmentally

friendly, abundant and low cost ever since Fujishima and Honda claimed a total efficiency of solar energy

conversion to hydrogen of only 0.4% using a TiO2 single crystal

as photoanode and Pt as cathode involving a chemical bias imposed by pH

difference between the electrodes[4-5].

Recently, photoanodes with TiO2-based film have been investigated

using techniques like anodization[6-11] and sputtering[12]. The aforementioned

nanotube-film on titanium foil by anodization has been of our great interest

for a system of light-sensitized enzymatic hydrogen production.

In this article, different approach using a light-sensitized enzymatic(LSE) system has been proposed. The LSE is a way of producing hydrogen by coupling an inorganic

semiconductor with enzymes in a photoelectrochemical configuration. The system uses the intrinsic proton

reduction ability of hydrogenase enzyme in

tandem with an anodic compartment

where the electron donors like water undergo oxidative reaction on light-sensitized photoanode. Generated electrons are separated and moved

through an external circuit within a solar cell, which is applied for an

external bias, to the cathodic compartment and used for the reduction of proton

into hydrogen on the active sites of enzymes. Oxidized ions move to the

cathodic compartment through an ion bridge like nanofiltration(NF) membrane in

this study.

Our present work aims to give optimized system

condition concerning photoanode of the anodized tubular TiO2 film on

titanium substrate and proton-reducing enzymes to produce hydrogen, a

renewable, nonpolluting and portable energy source. The trend of the system on

the light-sensitized enzymatic splitting of water was then investigated.

2.

EXPERIMENTAL

2.1.

Sample preparation

All

chemicals were used without further purification. P25 TiO2(Degussa, FRG) was used as a reference

when methylene blue(MB, 95% Showa

chemical, Japan) was used as the probe compound for measuring photocatalytic activity of anodized tubular TiO2

electrode(ATTE). Titanium

foils(0.25 mm thick, 99.6% purity,

2.2. Apparatus and

Analysis

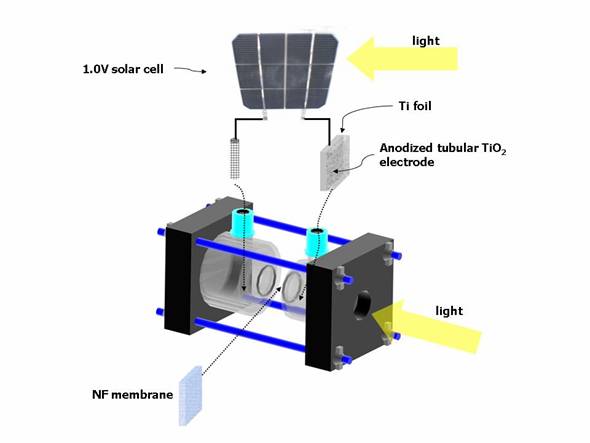

Experiments were mainly conducted in a

two-compartment(anodic and cathodic elements

connected via a nanofiltration

membrane, NF) reactor, as shown in

Fig. 1. The anodic

compartment had a volume of 80 ml(headspace volume ca. 55 ml) and

was a cylindrical-shaped cell. The

anodic compartment contains an

aqueous solution of 1.0M KOH for water splitting unless otherwise noted.

The cathodic compartment was a water-jacketed, cylindrical-shaped cell(80 ml, headspace volume ca. 55 ml) with

Tris-HCl buffer sealed with a silicone rubber gasket. Prior to the reaction, the mixture was

de-aerated with nitrogen gas for 20 min to remove the oxygen in water and

headspace. Each of two terminals from a solar cell panel(10cm´10cm, crystalline silicon, max. 1.0V) was

attached to the ATTE and the

platinum mesh cathode to apply external bias into the system. The light

source used was a 1000 W xenon

lamp(

Figure

1. Schematic view of the reactor with anodized tubular TiO2 photoanode,

solar cell

and NF membrane for hydrogen production.

3.

RESULTS AND DISCUSSION

The prepared samples anodized in 0.5M H3PO4+0.14M

NaF+0.1M NaNO3 have tubular(20V of bias, tube length ca. 600 nm) or

web-shaped(30V, thickness ca. 618 nm) TiO2 film on the Ti

substrates. The morphology of porous film was illustrated to change with

electrolytes, concentration of electrolytes, pH of electrolytes, anodizing time

and temperature, and the annealing ambient. This is due to the fact that during

the anodization porous structures are formed through two processes:

field-enhanced oxidation and field-enhanced oxide dissolution. And also, at elevated temperature solid-state sintering is

likely to take place, which leads to grain growth, densification and complete

collapse of the structure that are more remarkable during phase

transformations. The phase transformations often accompany bond-breaking and

enhanced mass transport[6-11]. XRD

analysis of the selected samples indicated

main characteristic anatase peaks

at 2q=25.3 with that of the commercial P25 indicated as a reference when annealed at

lower than 450ºC while rutile

peaks at higher than 500ºC. Ratio of constituents(oxygen

to titanium) of TiO2 film was calculated by EDAX results, which

resulted in the range from 0.1 to 2.4.

Photocatalytic activity of the ATTE

was firstly checked with MB discoloration. The time-coursed profiles of MB discoloration with

the samples along with P25 as a

reference. Unlike P25, the samples revealed lower activity in MB discoloration irrespective of species, while lower dose of P25 showed similar profiles to

the prepared samples. The

Langmuir-Hinshelwood kinetics, generally applied in photocatalysis, indicates

that a relatively high concentration of a probe material converts the equation

to zero order kinetics, evidenced in our study by the simple experiment of

varying the amount of P25 with a

fixed initial concentration of MB(10 ppm) in order to change the time-coursed

profiles of MB discoloration from first order to zero order with decreasing

injection amount. The calculated amount

of TiO2 on Ti substrate(2cm´2cm) turned out 1.6 ~ 3.1mg, assuming that film

thickness is in the range of 1 ~ 2 μm and density of TiO2 is

3.9 g/cm3. This amount is about one tenth of P25(200mg initially).

This is well correlated with the fact that less than 5 mg of P25 showed similar

discoloration rate to the prepared samples.

Secondly, the ATTE itself was irradiated in

0.1M Na2S electrolyte and hydrogen at a rate of ca. 40 μmol/(hr´cm2) was evolved. In this case, Na2S

acted as an electron donor and the ATTE excited the electrons in valence

band(VB) into conduction band(CB), which reduced the protons into hydrogen.

Anodization and annealing condition changed the time profiles of photocatalytic

hydrogen production. Web-shaped TiO2 films were inferior to tubular

TiO2 film such as sample no. 6. It was reported by Khan et al.[13]

that instead of the 3D configuration of particles, fabrication of vertical

standing nano-wires of TiO2 could improve the efficiency. During H2

was produced, the color of the solution in TiO2 film side turned

yellow gradually. This might due to the oxidation of sulfide ion to sulfur(Eo

= -0.47627 vs. SHE). Evacuation of evolved gas in headspace was repeatedly

carried out when the evolution rate decreased, recovering the initial rate.

Hydrogen production or evolution out of water seemed to be dependent of

pressure. Without Na2S a few amount of hydrogen(ca. 0.3 μmol/hr) was produced. When Na2SO3 was added, the solution in

TiO2 film side stayed transparent. In this case, sulfide ion was not

fully oxidized into sulfur, but into S22-(Eo =

-0.42836 vs. SHE). Possible reactions are as follows:

2S2- + 2h+VB → S22- (1)

S22- + SO32- → S2O32- + S2- (2)

S2O32- + 4h+VB + 6OH- → 2SO32- + 3H2O (3)

SO32- + 2h+VB + 2OH- → SO42- + 3H2O (4)

2SO42- + 2h+VB → S2O62- (5)

2H2O + 2e-CB → H2

+

2OH- (6)

Effect of others electrolytes such as 1.0M KOH,

0.1M NaOH, seawater, 0.1M K2SO4 or 1M KCl on the amount

of hydrogen was investigated, resulting in a rate of far less than 1

μmol/(hr´cm2).

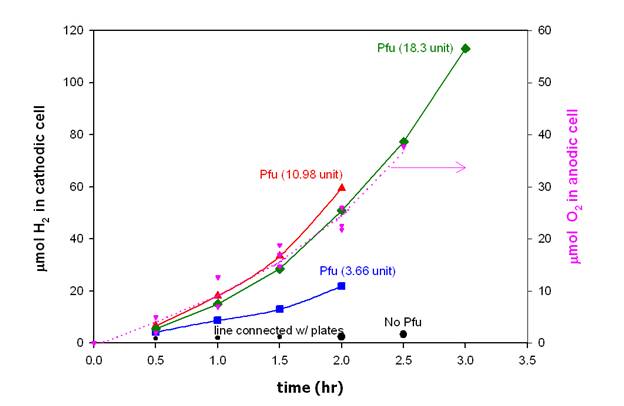

Figure 2.

Time-coursed profile of enzymatic

hydrogen evolution with the anodized tubular TiO2

photoanode(annealed at 550ºC, 1.0M

KOH in anodic compartment, Tris-HCl buffer in cathodic compartment, irradiated

photoanode area 1.0 cm2, ca. 68 mW/cm2 irradiation with

Xe lamp).

Thirdly, enzymatic hydrogen

evolution in cathodic compartment with oxygen evolved in the anodic compartment

was conducted with external bias(ca. 1.0V) applied by a solar cell. Previously,

applied potential and its effect was examined with a potentiostat from -1.5V ~

+1.5V. Working electrode(WE) was

placed on either the photoanode(P25 on ITO substrate) or the Pt cathode, while

counter electrode(CE) was on the rest with reference electrode(RE), Ag/AgCl in

saturated KCl. Then, external bias was applied onto the WE by potentiostat from

-1.5 to +1.5V. Positive bias onto the photoanode or negative bias onto the Pt cathode

generated respective negative current or positive current indicating an

electron flow from the photoanode to the cathode for both cases. This upward

shift of the anodic energy level led hydrogen evolution in the cathode

compartment. Otherwise, completely opposite results were obtained without any

hydrogen evolution. Noticeable hydrogen evolution was identified at a photocurrent above

300 μA when 1.3 V bias in absolute value was applied to the electrode. After the aforementioned check-ups, both a solar cell and a photoanode

were irradiated to increase the Fermi level and to excite electrons in the VB

into the CB of the photoanode. This system configuration led to the

stoichiometric evolution of H2 and O2(H2:O2=2:1).

Without any electron donor in the anodic compartment, oxygen was produced at a

rate of ca. 15 μmol/(hr´cm2) and hydrogen was produced in the cathodic compartment at a

rate of ca. 30 μmol/(hr´cm2). It revealed the rate of hydrogen production was ca. 30

μmol/(hr´cm2), which could be translated into ca. 6.75 L/(hr´m2). On a fine sunny day for 6.5 hrs

in the area of 104 m2(100m´100m), 439,000 L of H2 could be

evolved by rough calculation. Assuming that a fuel cell vehicle needs 4.6 kg of

H2 for 395 km, 439,000L of H2 is for more than ten

vehicles to be charged and for 3,352 km in distance.

4.

CONCLUSIONS

For

hydrogen production with solar irradiation in the future, a relatively novel approach was described where sensitized photoanode donates electrons to hydrogenase

that in turn reduces protons into

hydrogen. Vertical standing nanotubes of TiO2 film was stably operating as

a light sensitizer, evolving oxygen and enzymes were efficiently reducing

protons into hydrogen. Practically feasible system configuration was also

investigated replacing a salt bridge with nanofiltration membrane. To increase

the amount of harvested light, longer TiO2 tube with optimum

crystallinity has been under considered.

Acknowledgements

This

research was performed for the

REFERENCES

1. G. B. Raupp, A. Alexiadis, M. Hossain, and R. Changrani, Catalysis Today, 69, 41 (2001).

2. M. Ashokkumar, “An overview on semiconductor

particulate systems for photoreduction of hydrogen”, Int. J. Hydrogen Energy, 23(6), 427-438 (1998).

3. M. Ni, M.K.H. Leung, D.Y.C. Leung, and K.

Sumathy, Renewable and Sustainable Energy

Reviews, 11, 401 (2007).

4. T. Bak, J. Nowotny, M. Rekas, and C. C. Sorrell, Int. J. Hydrogen Energy, 27(1), 19 (2002).

5. T. Bak, J. Nowotny, M. Rekas, and C. C.

Sorrell, Int.

J. Hydrogen Energy, 27(2), 991 (2002).

6. D. Gong, C.A. Grimes, O.K. Varghese, W. Hu,

R.S. Singh, Z. Chen, and E. C. Dickey, “Titanium oxide nanotube arrays prepared

by anodic oxidation”, J. Mater. Res.,

16(12), 3331-3334 (2001).

7. O.K. Varghese, D. Gong, M. Paulose, C.A.

Grimes, and E. C. Dickey, “Crystallization and high-temperature structural

thermal stability of titanium oxide nanotube arrays”, J. Mater. Res., 18(1), 156-165 (2003).

8. G. K. Mor, O. K. Vargheese, M. Paulose, N.

Mukherjee, and C. A. Grimes, J. Mater.

Res. 18, 2588-2591 (2003).

9. G. K. Mor, K. Shankar, M. Paulose, O. K.

Vargheese, and C. A. Grimes, Nanoletters

5, 191-195 (2005).

10. M. Paulose, G. K. Mor, O. K. Vargheese, K.

Shankar, and C. A. Grimes, J. Photochem.

Photobiol. A:Chem. 178, 8-15 (2006).

11. K. S.

Raja, V. K. Mahajan, and M. Misra, J. of

Power Sources, 159, 1258-1265 (2006).

12. M. Kitano, M. Takeuchi, M. Matsuoka, J. M.

Thomas, and M. Anpo, Catalysis Today

120, 133-138 (2007).

13. S.U.M. Khan and T. Sultana, Solar Energy Materials and Solar Cells

76, 211-221 (2003).

[ BWW Society Home Page ]

© 2007 The Bibliotheque: World Wide Society