Preparation

and Photocatalytic Activity of Nano-sized Metal

Supported TiO2-Coated

on POF

Dr. Jin-Wook Ha and Dong-sik Yu

Dept.

of Chemical and Environmental

ABSTRACT

The photodegradation of IPA according to coating conditions was

examined by TiO2-coated POF. In the photoactivity of TiO2-coated

POF, ethanol solvent was higher activity than other solvents.

Inorganic(KR-400), organic(A-9540) and inorganic∙organic hybrid(GPTMS,

TMOS) resins were used as binder. Organic binder(A-9540) showed the highest

activity for photodegradation of IPA. But organic binder was decomposed by TiO2,

inorganic binder had lower binder ability than others, but inorganic binders

were lower adhesive than organic binders. The optimum activity obtained when

the ratio of TMOS and P-25 was 0.05~1:1.

1. INTRODUCTION

Photocatalysis is attracting a great deal of attention from view

points of fundamental science and applications for practical use. The

photocatalytic degradation of pollutants using photocatalysis is attracting

considerable attention for the application to environmental problems[1-3].

Among the various photocatalytic material, TiO2 has attracted wide

interest for its potential use in environmental purification. Recently,

Photochemical degradation has been commercially applied to environmental

cleaning by utilizing photocatalytic oxidation of volatile organic

compounds(VOC) by TiO2 powers or coating[4,5]. This photocatalytic

method is based on the reactive properties of electron-hole pairs generated in

the semiconductor particles under illumination by light of energy greater than

the semiconductor band gap energy. These charge carriers can reach the particle

surface and react with species in solution with suitable redox potentials[6,7].

While various research areas on photocatalysis have been studied, the

immobilization of photocatalyst on a specific substrate, in particular,

has received considerable attention due to the versatility of application. In

this study, plastic optical fibers(POF) were considered as light-transmitting

media and substrates for the potential use in photocatalytic environmental

purification system, comparing with that of quartz optical fibers(QOF). It is

concluded that the use of POF is preferred to QOF since the advantages such as

ease of handling, lower cost, relatively reasonable light attenuation at the

wavelength of near 400nm can be obtained. And also, this system has been

identified to achieve two main goals; transfer of light and volumetric reaction

among the various immobilized reactor system[8]. In some studies, solid-gas

phase heterogeneous photocatalysis using TiO2 has attracted

considerable interest for VOC removal, in particular due to the possible use

solar radiation, and numerous applications have been proposed[9]. A large

variety of organic compounds may be oxidized by TiO2 photocatalysis

in the presence of molecular oxygen. For instance, some authors studied in a

project on air quality the photocatalyzed oxodation of oxygenated compounds,

such as acetone, 1-butanol, butanal, formaldehyde and m-xylene, detected at

working places[10]. we have been interest in the photocatalytic degradation of

aliphatic compounds bearing an alcohol and we have chosen isopropyl alcohol

(IPA) as model compounds.

In this paper, we performed deposition of TiO2-coatings

on POF, and the effectiveness of photocatalytic degradation of IPA was

investigated under several coating conditions.

2. EXPERIMENTAL

2.1. Materials

Almost Chemicals were of reagent grade and used without further

purification. Ethanol, isopropyl alcohol, tert-butyl alcohol, acetone,

1-octanol from Aldrich; TiO2 from Degussa P-25; Plastic optical

fibers(POF), Binder(Aâ-9540, KRâ-400 GPTMS; 3-Glycidoxypropyltrimethoxysilane, TMOS; Tetramethyl

orthosilicate) from commercial grade.

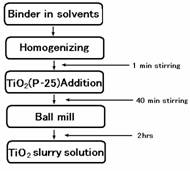

2.2. Preparation of TiO2-coating

slurry solution

TiO2 slurry was prepared with known amount of TiO2

in selected solvents and stirred before introducing the support. Selected

binders and diluting solvents were mixed for 1min at room

temperature. This binder mixture was added to TiO2 slurry for

40 min and were performed ball mill for 2hr. Fig. 1 shows the preparation

of TiO2-coating slurry solution.

Fig.

1. Preparation of TiO2-coating slurry solution.

2.3. Plastic optical

fibers(POF) pretreatment

Pretreatment of POF could not be done either thermally or

physically because the materials of core and clad is very similar to each

other. Solvation using appropriate solvent was finally chosen to remove the

clad of POF. After removing the clad from POF with 1mm diameter, the resulted

diameter should be closed to 0.98mm(matched with data by supplier). Clear proof

of change in diameter of the POF was obtained by SEM(JSM 5900, JEOL) taken at

various time scales.

2.4. Dip coating

The POF were dipped in the slurry solution by hand in an

atmosphere. After each coated POF was allowed to dry at 80℃ for 2hr.

2.5. Experimental set-up

A schematic representation of the experimental set-up used for

performing photocatalytic degradation processes at the solid-gas interface is

given in Fig. 2. The whole configuration consists of a light source(Sankyo

Denki, 8W, BLB UV lamp, 2EA), pyrex reactor(730ml, cylinder cell type),

thermocontroller, Gas chromatography(GC: Young Rin, Column: HP-1, 30m × 0.321mm

× 0.25 ㎛, 60℃ to 325℃, Oven Temp. 30℃ , Injector Temp. 150℃, Detector Temp. 200℃), Carrier gas(N2/O2/H2),

Detector(FID). The system was covered with aluminum foil which served as light

reflector.

Fig.

2. Schematic diagram of the experimental set-up: 1. UV lamp; 2. photoreactor;

3.

sampling port; 4. foiled chamber; 5. cooling fan; 6. thermocontroller.

2.6. Photodegradation of IPA

under several coating conditions on POF

The POF of 30cm units was soaked in acetone for 90 sec, pulled it

out and washed with distilled water. TiO2 slurry solution consisted

of TiO2, binder and ethanol. The weight ratio of TiO2/binder/ethanol

was 0.05/1/5.6, respectively. We used several binders such as inorganic

binder(KR-400), organic binder(A-9540) and inorganic∙organic

hybrid(GPTMS∙TMOS) resins. Furthermore, the ratio of TMOS : TiO2

was from 0.05 to 1. This slurry solution was treated by ball mill at 300 rpm

for 2hr. Pretreated POF were dipped into the stirred 15wt% TiO2

slurry solution and then oven-dried at 80℃ for 2hr. TiO2-coated

POF were moved to reactor. The inner temperature of reactor was maintained at

25℃. IPA 430ppm was injected in reactor. When thermal and diffusion

state is stable. then, UV light source was turned on. Photodegradating sample

was transferred to a GC by syringe in 0.5ml scale per few minute intervals. The

present study identified the target IPA by retention times using GC/FID

analysis.

3. RESULTS AND DISCUSSION

3.1. Influence of the amount

of TiO2

The preliminary processes were examined on the surface of

PMMA(polymethyl methacrylate) instead of POF, in order to identify the

influence of the amount of TiO2 on the photodegradation of IPA. As

seen in Fig. 3, the efficiency of the photodegradation of IPA was proportional

to the amount of TiO2(0.01g, 0.02, 0.03g).

Fig. 3. The influence of the amount of TiO2(0.01g,

0.02, 0.03g) on the photodegradation of IPA.

3.2. Effect of the IPA

concentration

Fig. 4 shown the effect of the IPA concentrations (215, 430,

1000ppm) using TiO2 0.02g as the previous results. For all three IPA

concentrations, the tendency of IPA degradation showed the similar

pattern. The photodegradation efficiencies were about 80% for 215ppm at

retention time 9.5 min, nearly 100% for 1000ppm at retention time 24min.

Fig.

4. The effect of the IPA concentrations (215, 430, 1000ppm) on TiO2

0.02g.

3.3. Effect of diluting

solvents on TiO2 dispersion

Degradation profiles were shown in Fig. 5 with data for several

solvents such as ethanol, tert-butyl alcohol, 1-octanol, from low to

high-chained alcohols. The photodegradation efficiency was essentially

dependent of the diluting solvents used in the coating processes. As shown,

Ethanol exhibited higher performance than other solvents, 1-octanol was lower

performance. From results, the effect of IPA photodegradation decreased with an

increase in the carbon chain number.

Fig.

5. Effect of diluting solvents on TiO2 dispersion

3.4. Effect of binders

As the previous results, we have used ethanol as

diluting solvent. The dependence of binders on the photodegradation of IPA has

been studied using binders such as Inorganic(KR-400), organic(A-9540) and

inorganic∙organic hybrid(GPTMS, TMOS) resin. The weight % of TiO2(P-25)

contains 15wt%. Fig. 6 shows the results of binders to the same 15wt% P-25 and

ethanol on POF. From the figure, photodegadation activities of IPA on POF

decreased on the binder GPTMS than other binders. Organic binder(A-9540)

showed the highest activity for IPA degradation. It is known that this

activities difference decrease with increasing carbon-chain length. This reason

is similar well-known original photocatalytic phenomenon, which leads to the

breakdown of organics[11], Deduced other reasons is UV reflection and UV

adsorption of binder.

Fig. 6. The dependence of binders on 15wt% P-25 and

ethanol.

3.5. Effect of the amount of TMOS

Organic binders was decomposed by photocatalyst, inorganic binders

were lower adhesive than organic binders. Then, we have adopted the use

of inorganic∙organic hybrid(GPTMS, TMOS) resins as binder, ethanol as

diluting solvent, 15wt% P-25 as TiO2. The ratio of TMOS to P-25 was

0.05∼0.1. The Comparatively activity of

the amount of TMOS can be seen from Fig. 7. Increased amounts of TMOS decreased

the activity of TiO2-coated POF. The amount of TMOS was less , the

activity was more. As shown in figure, the zero amount of TMOS were the most

active. From these results, the least amount of TMOS as binder in

the coating conditions on POF was needed to exhibit an effective

photodegradation of IPA.

Fig.

7. Comparison of IPA photodegradation activities with difference

TMOS/P-25= 0; 0.05; 0.1.

4. CONCLUSIONS

This study showed that the photodegradation of IPA on POF were

examined under TiO2-coating condtions. The photodegradation

efficiency of IPA decreased with an increase in the carbon chain number.

Ethanol exhibited higher performance than other solvents. Organic

binder(A-9540) among inorganic(KR-400), organic(A-9540) and

inorganic∙organic hybrid(GPTMS, TMOS) resins as binders showed the

highest activity for IPA degradation. we have adopted the use of

inorganic∙organic hybrid(GPTMS, TMOS) resins as binder. The ratio of TMOS

to P-25 was 0.05∼0.1. Increased

amounts of TMOS decreased the activity of TiO2-coated POF. The least

amount of TMOS as binder in the coating conditions on POF was needed to exhibit

an effective photodegradation of IPA.

REFERENCES

1. T. Hisanaga, K. Harada, K. Tanaka, J. Photochem.

Photobiol. A: Chem., 54, 113(1990).

2. A. Bouzaza, A. Laplanche, J. Photochem. Photobiol. A:

Chem., 150, 207(2002).

3. A. Mills, R. H. Davies, D. Worsley, Chem. Soc. Rev., 417(1993).

4. F. W. Wilkins, D. M. Blake, Chem.

5. H. Yammashita, M. Harada,

J. Misaka, M. Takeuchi, K. Ikeue, M. Anpo, J. Photochem.

Photobiol.A:

Chem., 148, 257(2002).

6. A. J. Bard, J. Phys. Chem., 86, 172(1982).

7. G. Hodes, M. Gratzel, Nouv. J. Chem., 8, 509(1984).

8. R. Sun, A. Nakajima,

136, 111(2000).

9. Y. Ohko, A. Fujishima, K. Hashimoto, J. Phys. Chem., B 102,

1724(1998).

10. J. Péral, D. F. Ollis, J. Catal., 136, 554(1992).

[ BWW Society Home Page ]

© 2005 The BWW Society/The Institute for the Advancement of Positive Global Solutions