Kinetics

for the Formation of YBa2Cu3Oy Superconductors

from the Oxide Precursor Containing BaCuO2.5

by

Dr. Hai-woong Park and Dr. Jin-Wook Ha*

Department of Advanced

Materials

*Department of Environmental

Abstract

The oxide precursor containing BaCuO2.5, Y2O3

and CuO with overall composition of Y: Ba: Cu: O= 1: 2: 3: 7.4 was synthesized

from metallic Y, metallic Cu and Ba(NO3)2 at 600℃. The precursor was

successfully converted to the superconducting Y123 orthorhombic phase with heat

treatment at 900~1020℃ in

air without an additional oxygenation process at low temperature. For the

precursor powder, the orthorhombic Y123 superconducting phase was directly

formed within 10 minutes. In the case of the 1mm thick silver-sheathed sample,

Y123 superconducting phase was obtained after soaking for 30 minutes. at 950℃ and cooled at 100℃/h in air. In the melt

processing of the pellet samples at 1020℃, the superconducting phase was formed

within 30 minutes. The directly formed superconducting phases at high

temperature from both the silver-sheathed and the pellets showed 92K of the

critical temperature.

1. INTRODUCTION

In the synthesis of YBa2Cu3Oy(Y123)

superconductor, many researchers have used Y2O3-BaO-CuO

system as a starting materials. The carbonate(BaCO3) in the system is

difficult to decompose even at high temperature and such high temperature

easily result in particle coarsening before sintering[1, 2]. Studies of this

system[3] also indicated that the value of y in the YBa2Cu3Oy

varied with oxygen partial pressure and temperature. The oxygen solubility in

Y123 vary continuously for the composition range corresponding to values of y

of about 6.3-7.5. Because of such phase equilibrium and relatively low

temperature during the oxygenation process, the probability of forming a

non-superconducting phase is very high.

From the conventional processes, the end product is a

tetragonal YBa2Cu3Oy, y=6.3~6.6 which need to

be oxygenated to the orthorhombic YBa2Cu3Oy, y≈7.0.

Since the rate of oxygen diffusion through Y123 is very slow and the tendency

of the sample to form microcracks during oxygenation process limit

superconducting properties and sample sizes[4, 5].

In the previous studies[6, 7], a two stage processing was

successfully applied for the synthesis of bulk Y123 superconductors via the

intermediated precursor(IP). The intermediate precursor was produced by

attrition milling of suitable starting materials and subsequent heat treatment

in air. The attrition milling generate finer powder and reduce milling time

compared to conventional milling. During attrition milling, starting powders

were refined to submicron scale through repeated cold welding and fracture, and

they were converted to BaCuO2.5, Y2O3 and CuO in

a subsequent heat treatment. The

intermediate precursor contained the overall composition of Y: Ba: Cu: O = 1: 2:

3: Z, Z>7.0 where the oxygen content of the intermediated precursor was

higher than that of the orthorhombic Y123. In both the thermomechanical processing

of the bulk sample at 900~950℃

and the melt processing at 1020℃,

the intermediate precursor were utilized for the formation of bulk Y123

superconductors through the direct participation of BaCuO2.5. In

this approach, orthorhombic Y123 was directly obtained without additional

oxygenation process and thus the difficulty of an additional oxygenation

process in dense bulk samples can be avoided.

The objective of this work is to study the appropriate

thermodynamic and kinetic conditions in both silver-sheathed and bulk Y123

samples for the direct formation of orthorhombic Y123 at 950~1020℃ in ambient air from the

oxide precursor.

2.

EXPERIMENTAL PROCEDURE

In this study, Y123 superconducting phase was synthesized

in two stage processes. In the first stage, an intermediate precursor was

synthesized via high energy milling and subsequent heat treatment from the

starting powders. In the second stage, the IP was converted into high

temperature superconductors through thermomechanical processing or heat

treatment.

2.1

Synthesis of the IP

The high purity powders of metallic yttrium, metallic

copper and barium nitrate were used as starting chemicals. The starting powders

were milled for 20~65 hours in an attritor. Then the composite powder was heat

treated at 600℃ in

an argon environment. The milled powder was carefully heated to 600℃ under a continuous stream

of high purity argon gas. After 5 hours of holding at the peak temperature, the

powder was cooled to room temperature.

2.2

Heat treatment of the IP precursor powder

To determine the nature of the reactions and intermediate

phases appearing during the formation of the Y123 compound, a series of rapid

heat, soak, and quench experiments for the powder precursor were conducted at

selected temperatures. In these series of experiments, 0.5g of precursor was

introduced into a furnace preheated at 10~15℃ above of each endothermic peaks in DTA

and then soaked for 1~300 minutes in air.

2.3

Thermomechanical processing of silver-sheathed sample

The IP powder was packed inside the silver tube by

powder-in-tube techniques or cold pressed into pellet form. The silver-sheathed

samples were deformed mechanically by repeated cold swagging or hot rolling.

The packed tube was cold swagged for 75%. After swagging, the tube was cut to

short pieces and sealed by a die forge. The samples were placed in a preheated

furnace chamber at 950℃.

The samples were rolled repeatedly until the final thickness of the sample

reached to the predetermined value. After the thermomechanical processing,

various types of heat treatment experiment were conducted where the peak

temperatures, soaking time, and cooling rates were varied within the range of 900~950℃. At 900℃, the rolled samples were

held for 30~90 minutes by 15℃/h

to 900℃

and by 100℃/h

to room temperature. The samples were also held for 30 minutes at 950℃ and the cooling rate was

varied.

2.4

Pellet sample

The weighed precursor was formed into 0.64cm diameter and

0.1cm thickness by 300MPa uniaxial pressure. The green density of the formed

powder was obtained by geometrical condition. The density of the pellets were

about 4.2g/㎤.

After forming the IP into pellet form, various types of rapid heat, soak and

cooling experiments were conducted at 1020℃. Through these experiments, reaction

time for the formation of Y123 was determined. The samples were also held for

30~60 minutes at 1020℃

and the cooling rate of the pellets were varied from air quenching to 5℃/h. The environment of the

furnace was controlled by flowing air during heat treatment.

2.5

Characterization

The powder samples were analyzed with various techniques.

The chemical compositions or phase evolution of the samples were analyzed by

XRD. TGA experiment was performed to measure the weight change of the powder IP

or bulk samples during heating process. For the powder IP, the powder was

loaded into a platinum boat at room temperature. The sample was heated to 950℃ at 5 or 50℃/min in air flow. The

weight loss of powder was measured with respect to time. For bulk samples, a

1mm thick and 2.5mm diameter sample at room temperature was inserted into the

TGA equipment which was preheated to 950℃.

3. RESULTS AND DISCUSSION

In the previous works[6, 7], we successfully synthesized the

IP consisting of Y2O3, BaCuO2.5 and CuO from

the metallic Y, metallic Cu and Ba(NO3)2 via high energy

attrition milling and appropriate heat treatment at 600℃. The formed precursor

contains higher oxygen content than that of orthorhombic Y123 superconducting

phase which requires oxygen content of 6.8~7.0. The IP powders were directly

converted to orthorhombic Y123 phase at high temperature without an additional

oxygenation process at low temperature. These results were due to the slow

decomposition of BaCuO2.5 at a fast heating rate. During the

decomposition of BaCuO2.5 to BaCuO2, the BaCuO2.5

phase release its excess oxygen and result in formation of orthorhombic Y123

superconducting phase.

3.1 Kinetic for the formation of orthorhombic Y123

Orthorhombic Y123 phase is not stable at high temperature[8].

Kishio et al.[9] showed that the oxygen content of Y123 at high temperature

decreased as a function of time due to oxygen diffusion. As shown in figure 1,

orthorhombic Y123 phase formed in early stage of heat treatment at 900~1020℃ transformed to tetragonal

Y123 when the soaking time increased to 300 minutes. Therefore, it is necessary

to reduce the temperature after the conversion of the precursor to orthorhombic

Y123 phase. In order to determine kinetic conditions for the formation of

orthorhombic Y123, we conducted two different series of experiments. First, we

determined the minimum reaction times at 900~1020℃ through a series of rapid heat, soak,

and quench experiments in air environment. Second, we performed a TGA

experiment for a bulk sample in air to calculate the oxygen content of the bulk

sample. In the TGA study, the bulk sample was rapidly heated to 950℃.

Figure

1. XRD

patterns of heat treated IP in rapid heat, soak and quench experiments.

3.1.1

Minimum reaction time at 950-954℃

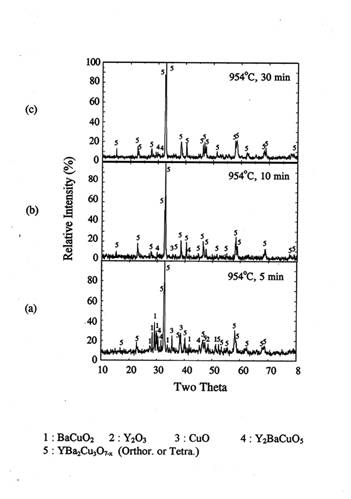

Figure 2 show the XRD patterns for the powder

precursors(0.5g) which were rapidly heated at 954℃, soaked for 5, 10, or 30 minutes and

quenched to room temperature.

Orthorhombic Y123 phase was the main peak after 5 minutes

holding at 954℃.

Some amount of BaCuO2 and CuO peaks were also detected. When the

soaking time increased to 10 minutes, only orthorhombic Y123 phase and traces

of 211 were obtained. The XRD pattern after 30 minutes also shows orthorhombic

Y123 and traces of 211. We think that the small amount of 211 phase detected in

figure 2(b) and (c) was formed by the peritectic reaction between Y123 and

CuO because it was not formed until 5 minutes holding at 954℃[10]. Therefore, the

reaction for the formation of the orthorhombic Y123 powder IP was completed

within 10 minutes at 954℃.

Figure

2. XRD of

the powder IP after rapid heat, soak and quench at 954℃ in air.

The pellet samples(P1) were rapidly heated to 950℃ and held for 2, 5, 10, and

30 minutes and subsequently quenched in air. Figure 3 shows the XRD patterns of

the quenched bulk samples.

During early stages of reaction(2 min, figure 3(a)),

BaCuO2.5 was present along with the reaction product Y123 and the

reactants Y2O3 and CuO. An appreciable amount of BaCuO2

was also present. As the reaction progressed for 5 minutes(figure 3(b)), BaCuO2.5

disappeared completely and the peaks of BaCuO2 also decreased

drastically. Orthorhombic Y123 peak became predominant. After 10 minutes of

reaction, only orthorhombic Y123 with traces of 211 phases were observed. After

30 minutes holding, XRD pattern shows no difference with that in the case of 10

minutes holding case. Therefore, the formation of orthorhombic Y123 phase was

completed within 10 minutes.

Figure 3. XRD of the

pellet IP after rapid heat, soak and quench at 950℃ in air.

The above results suggest the minimum reaction time for

formation of orthorhombic Y123 phase at 950~954℃ was less than 10 minutes for both

powder and bulk samples and the reaction time was not affected by the sample

geometry in present condition. Ten minutes of reaction time at 950~954℃ is shorter than that of

the decomposition of BaCuO2.5 via equation 1.

BaCuO2.5

→ BaCuO2 + 0.5O2 [Eq. 1]

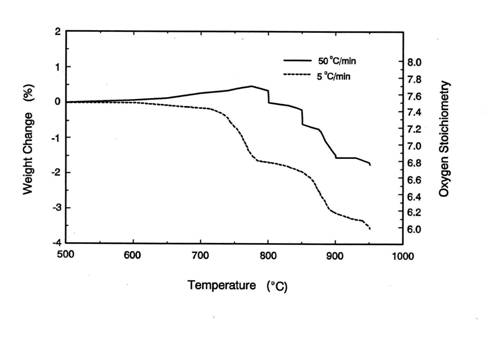

This is because in the TGA experiments at 50℃/min of heating rate shown

in figure 4, the sample was heated from room temperature to 950℃ in about 19 minutes and

during this period BaCuO2.5 did not decompose completely. Thus, at

950℃ or

higher temperature, the reaction kinetics for the formation of orthorhombic

Y123 from the IP is faster than the decomposition of BaCuO2.5 via

equation 1. In such a case, the undecomposed BaCuO2.5 can

participate in the formation of orthorhombic Y123.

Figure 4. The weight loss of the IP at different heating

rates in TGA experiments.

3.1.2

Weight loss of the bulk sample at 950℃

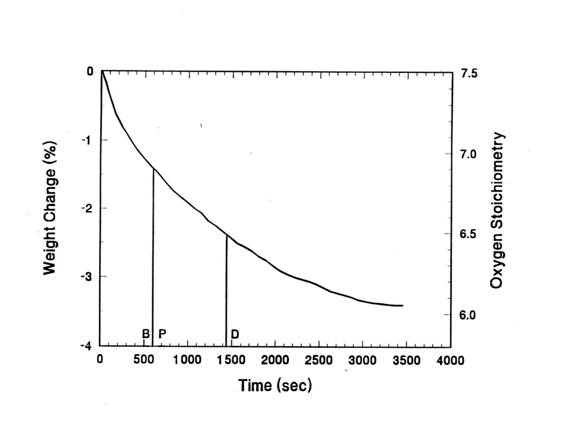

To estimate the decomposition period of orthorhombic Y123

phase, a TGA experiment for a pellet sample was conducted at 950℃. The dimension of the

pellet sample was 1㎜ in

thickness and 2.5㎜ in

diameter. Figure 5 shows the weight loss of the pellet with respect to time. In

this Figure, the Y: Ba: Cu: O molar ratio was also noted in the right Y axis.

From the weight loss of the sample, we calculated the oxygen content of the

sample.

The total weight loss of the sample after reaching to

steady state was about 3.5%. Since the initial oxygen content was 7.5, the

final oxygen content will be about 6.0. The total relaxation time of the sample

from 7.5 to 6.0 was about 58 minutes. The points P and B(10 min) in the time

axis represent the periods when the formation of orthorhombic Y123 from the

powder and bulk precursor were respectively completed.

The point D, where Y: Ba: Cu: O = 1: 2: 3: 6.5, correspond to the complete

decomposition of BaCuO2.5 to BaCuO2 via equation 1. The

point D is also consistent with an approximate transition temperature of

orthorhombic Y123 to tetragonal Y123 phase.

For the present conditions, the minimum reaction time for

the formation of orthorhombic Y123 in both powder(P) and bulk samples(B) were

far shorter than the time needed for complete decomposition of BaCuO2.5.

Figure

5. The weight loss of the pellet IP at 950℃ in air. P and B correspond to minimum time for the formation of orthorhombic Y123 in air

from powder and bulk IP. D represents the

composition

corresponding

to complete decomposition of BaCuO2.5.

In this situation, the undecomposed BaCuO2.5 can

participate to the formation of orthorhombic Y123 by equation 1. This result is

consistent with the observation of BaCuO2.5 in early stage of

heat treatment experiment of the bulk sample at 950℃ shown in figure 1. The TGA

result also suggests that the released oxygen from the partial decomposition of

BaCuO2.5 to BaCuO2 via equation 1 can be

retained inside the sample because the oxygen content at P and B is higher than

6.5. In this case, the retained oxygen will in-diffuse to tetragonal phase

during cooling process.

Umemura et al.[11] measured the weight loss in a dense

Y123 sintered sample (bulk density ≈91%) at 300~950℃. They estimated the

temperature dependence of the out-diffusion constant as Dout =3.7×10-5

exp(-0.50 ℮V/kBT). Tu et al.[12] also determined the

diffusivity of oxygen in orthorhombic polycrystalline in Y123(x=0) as D=0.035

exp(-1.3 ℮V/kT) [㎠/sec].

We calculated the estimated oxygen diffusion time of the 1㎜ thick bulk sample at 950℃ from Umemura and Tu's

results. The calculated oxygen diffusion times were about 35 and 69 minutes,

respectively. Even though our TGA result shows some discrepancies with

Umemura's value, it was very close with Tu's calculated relaxation time. The

result of TGA experiment for bulk sample at 950℃ suggests that the orthorhombic Y123

phase can be obtained without and additional oxygenation process if the

reaction time for a 1㎜

thick bulk sample is less than about 25 minutes. This TGA result is consistent

with the results of reaction time experiments.

3.2

Effects of cooling rate at 950℃

In this series of experiments, we prepared

silver-sheathed samples from the same batch of IP. We fixed all the

experimental conditions except cooling rate. The fixed experimental conditions

are shown in table 1.

Table 1. Experimental conditions for the silver-sheathed

samples

|

Parameters |

Specifications |

|

Milling time |

20h |

|

Heating rate(1st H.T.)a |

50℃/h |

|

Peak temperature(1st H.T.) |

600℃ |

|

Holing time(1st H.T.) |

5h |

|

Sample thickness |

3.2㎜(after swagging) |

|

|

1.0㎜(after hot rolling) |

|

Heating rate(2nd H.T.)b |

rapid heat |

|

Peak temperature(2nd H.T.) |

950℃ |

|

Holing time(2nd H.T.) |

30minutes |

a Heating rate for the formation of the

IP from the milled precursor.

b Heating rate for the formation of Y123

phase from the IP.

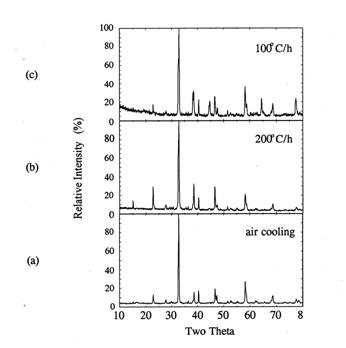

The silver-sheathed samples having 1 ㎜ in

thickness were rapidly heated to 950℃, soaked for 30 minutes and

subsequently cooled in purified air at different cooling rates. The cooling

rates were air quenching, 200℃/h,

and 100℃/h,

respectively. Figure 6 shows the XRD patterns of the cooled samples. All

samples show orthorhombic Y123 phase as observed by the relative intensities at

2ɵ=32.5~32.8° and

46.6~47.5°.

When the cooling rate decreased from air quenching to 200

or 100℃/h

in air, the relative intensities of orthorhombic Y123 peaks at (013)~(011)

doublet reflections between 2ɵ=32.5

and 32.8℃

showed larger separation. At 100℃/h cooling rate, 2ɵ values for (013) and (011) peaks were

32.7 and 32.9°, respectively. Based on the reference XRD data[13], these

2θ values match with those in YBa2Cu3O7 case.

This means that the total oxygen content of the sample is close to 7.0[13].

Figure 6. XRD of the

silver-sheathed samples which were heated to 950℃,

held for 30 minutes and

cooled at different cooling rates.

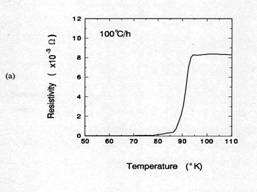

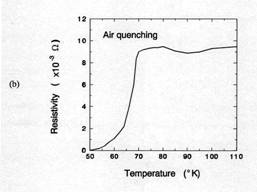

Figure 7 compared the critical transition temperatures(Tc)

for samples cooled at air quenching and 100℃/h. The air quenched sample shows that

an onset temperate for superconductor(Tc onset) was about 70K and

ΔTc was about 15K. From TGA result in figure 5, the oxygen

content of 1 ㎜

thick sample after 30 minutes holding at 950℃ was approximately 6.5. Orthorhombic Y123

phase having Y: Ba: Cu: O = 1: 2: 3: 6.5 shows the Tc onset≈

60-70K [14]. Therefore, the Tc onset in this case is consistent with

the value from TGA result. When the sample was cooled 100℃/h, Tc onset was

about 92K and ΔTc within 5K. This result suggests that the

total oxygen content of the sample is close to 7. The oxygen content of 7 is

consistent with XRD results.

XRD, TGA, and Tc results indicates that when a

bulk sample of 1㎜

thick was soaked for 30 minutes at 950℃ and cooled at 100℃/h in air environment,

additional oxygenation process is not necessary to form 92K Y123

superconductor. This reaction time for the formation of 92K Y123 superconductor

is much shorter time than that of other case. Okada et al.[15] reported that

Y123 superconductor in silver-sheathed samples was obtained through both

calcination at 950℃

for 5 hours and thermomechanical processing at 910℃ for 5 to 150 hours in

oxygen environment.

Figure 7. TC of

silver-sheathed samples. Sample having 1mm in thickness were

(a) air quenched and (b)

cooled at 100℃/h

in air after soaked 30 min at 950℃.

3.3

Melt processing of pellet samples

Melt processing has been used to improve the transport Jc

by obtaining a very dense and preferentially aligned microstructure. In

this study, it was possible to improve the superconducting quality during melt

processing because orthorhombic Y123 could be fabricated from high oxygen

precursor without additional oxygenation process. We conducted two series of

experiments. In these series of experiments, the precursor was formed into 0.27

㎝

thick and 1.25 ㎝

diameter pellets. In the first series, holding time at 1020℃ was varied from 2~30

minutes to find the minimum reaction time for the formation of the orthorhombic

Y123. In the second series, cooling rate was varied from air quenching to 5℃/h.

3.3.1

Reaction time for formation of orthorhombic Y123 at 1020℃

The samples were rapidly heated to 1020℃, held for 1,5, 10, 20, or

30 minutes in air, and quenched in air. Figure 8 shows the XRD patterns of the

melt processed samples for each processing conditions.

After 1 minute holding, some amount of orthorhombic Y123

phase was formed. The Y2O3, BaCuO2 and CuO

were remained as the major phase. After five minutes of reaction at 1020℃, orthorhombic Y123 was the

predominant phase and BaCuO2 and CuO phase were still remained.

Small amount of 211 phase was also detected in XRD. As the reaction time

increased more than 5 minutes, orthorhombic Y123 peaks increased and the

impurity peaks decreased appreciably. After 10minutes of reaction, the

orthorhombic Y123 phase was formed more than 95% and only trace of 211 and

BaCuO2 were remained. When reaction time increased to 30 minutes,

almost single orthorhombic Y123 phase was formed with trace of 211 phase.

Figure 8. XRD of the melt

processed pellets at 1020℃

for 1-30 min

and

quenched in air.

We think that trace of 211 and BaCuO2 phases

after 10 or 30 minutes holding are related to the melting of the Y123 phase

because of the following observations. First, the sample showed melting after

5~30 minutes heat treatment at 1020℃. Second, as shown in XRD patterns,

orthorhombic Y123 phase started to form even after 2 minutes of reaction and became

the primary peak after 5~30 minutes holding. It is well known that Y123 melted

incongruently to 211 plus a Ba-Cu rich liquid[16]. During cooling process, a

fast cooling cause a incomplete reverse reaction. The incomplete reaction leads

to the presence of 211 and the liquid phase of BaCuO2 and CuO.

Therefore, the above results indicate that the minimum reaction time for the

formation of orthorhombic Y123 at 1020℃ was about 10-30 minutes.

3.3.2 Cooling Rate Effects at 1020℃

In this series experiments, the samples were held for 30

minutes at 1020℃

and subsequently cooled at two different rate. Samples were cooled at 100℃/h to room temperature or

at 5℃/h to

920℃

and at 100℃/h

to room temperature. Figure 9 shows the XRD patterns of the samples. For the

comparison purpose, the XRD pattern for the air quenched sample was added in

(c).

Figure

9. XRD for the melt processed samples at 1020℃ with different heating rates.

(a) 100℃/h,

(b) 5℃/h

to 920℃

and 100℃/h,

(c) air quenching.

In all cases, the formed Y123 phases were orthorhombic.

As the cooling rate decreased from melting temperate, c-axis texturing in (001)

peaks became predominant. The better grain alignment with slower cooling rate

is related to the mass transport rate at the solid-liquid interface during melt

processing. Since the a-b plane is considered to be fast growth plane in Y123

superconductor[14], slow cooling rate around the melting temperature allows

sufficient time for mass transport along the ab plane and for nucleation along

the c-axis to occur.

4. CONCLUSIONS

1.

The synthesized intermediate precursor(IP) powder containing BaCuO2.5,

Y2O3 and CuO was successfully converted to orthorhombic

Y123 superconducting phase within 10 minutes at 954℃ when the powder was

rapidly heated to the peak temperature.

2.

For 1mm thick silver-clad samples, if the sample was soaked for 30 minutes at

950℃ and cooled at 100℃/h

in air, additional oxygenation process was not necessary to form 92K Y123

superconductor. From TGA result, this fast formation 92K superconductor is

presumably due to the direct conversion of BaCuO2.5 to orthorhombic

Y123 at high temperature.

3.

In the melt processing at 1020℃, the reaction for the

formation of orthorhombic Y123 in the 2.7mm thick IP pellet sample was

completed within 30 minutes. At the cooling rate of 5℃/min

to 920 ℃ and 100 ℃ to

room temperature in air, orthorhombic Y123 superconducting phase was obtained

without an additional oxygenation process at low temperature.

4.

As the cooling rate decreased from 100℃/min

to 5 ℃/min between the melting temperature

and 920℃, c-axis texturing in (001) peaks

became predominant due to faster mass transport rate along a-b plane and thus

faster grain growth.

REFERENCES

1.

G.

Selvaduray and C. Zhang, J. Mater. Res.

7, 283 (1992)

2.

T.

Nevriva, P.Holba, S.Durcok, D.Zemanova, E.Pollert and A.Trisk, Physica C, 157, 334 (1989)

3.

T.Aselag

and K. Keefer, J. Mater. Res., 3, 1279 (1988)

4.

M.Murakami,

Superconduc. Sci. Tech., 5, 185 (1992)

5.

J.L.

Taloni, D.M. Pooke, M.P. Staines, M.E. Bowden, N.E. Flower, R.G. Buckley, M.R.

Presland and R.C. Davis, Physica C, 171, 61, 1991

6.

7.

H.G.

Lee and

8.

D.E.

Morris, A.G. Markelz and J.H. Nickel, Physical

C, 168, 153 (1990)

9.

K.

Hishio, K. Suzuki, T. Hasegawa, T. Yamamoto, K. Kitazawa and K. Fueki, Solid State Chem., 82, 192 (1989)

10.

T.

Aselage and K. Keefer, J. Mater. Res.,

3, 1279 (1988)

11.

T.

Umemura, K. Egawa, M. Wakata and K. Yoshizaki, Jpn. J. Appl. Phys., 28,

L1945 (1989)

12.

K.N.

Tu, N.C. Yeh, S.I. Park and C.C. Tsuei., Phys.

Rev. B, 38, 5118 (1988)

13.

14.

K.

Salama, V. Selvamanickam and D.F. Lee, In processing and properties of High-Tc

Superconductors, eds. S. Jin, 155, Singapore, World Scientific (1993)

15.

M.

Okada, A. Okayama, T. Morimoto, T. Matsumoto, K. Aihara and S. Matsuda, Jpn. J. Appl. Phys., 27, L185 (1988)

[ BWW Society Home Page ]

© 2006 The BWW Society/The Institute for the Advancement of Positive Global Solutions