Management:

Corporate

Strategy for Dramatic Productivity:

Shortening Inspection Time by 90%

by

Professor Emeritus Akira Ishikawa

Former

Dean, GSIPEB

Senior

Research Fellow, ICC Institute,

Doctoral

Program Chair

Definition

of Radio Frequency Identification (RFID)

In

this section, I will discuss the technology of Radio Frequency Identification (RFID),

which is a way to identify objects using electromagnetic waves. In most cases,

it refers to technologies that can acquire/transmit information obtained from

tags containing ID information, via short-distance communications using

electromagnetic fields or radio waves.

Specifically,

a winning combination is to have Radio Frequency (RF) and Integrated Circuit

(IC) tags converge with the wireless technology of readers that can read its

data. However, since such tags can be attached to various objects and even onto

human beings, they can be useful in monitoring and verifying positions and

shifts in positions, and therefore reducing inspection times.

Speedy

and accurate distribution support

An

example is the distribution reforms through the application of a monitoring and

tracking system for pharmaceutical products via the use of RFIDs by Eisai

Distribution Co., Ltd. (Atsughi-shi, Kanagawa, President Jiro Kimura) and

Sato Holding Corporation (Meguro-ku,

A

feature of the system include a one-way use in the original packing (which is

easy to install) of psychotropic drugs, which require strict control. It is

also designed for shared use among several companies; in this case, factories,

distribution centers, and agencies.

Zero

Error

As

part of a “product substitution experiment” (which was carried out without informing

company workers), surprise inspections, which involved gauging the accuracy of

human inspections were carried out for a period of two months. The results

registered a 4% error rate. In contrast, when RFIDs were used, the results

showed a completely error-free, 100% accuracy rate.

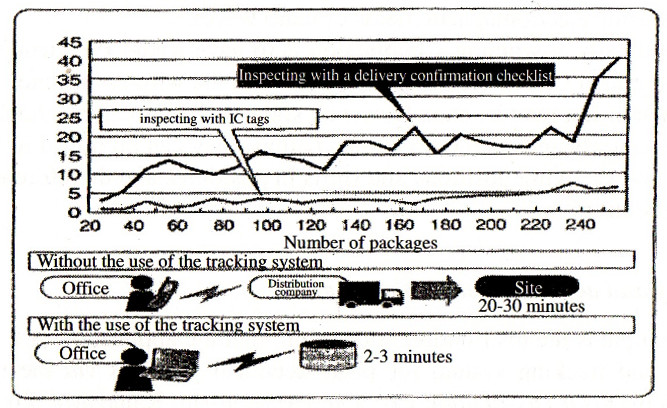

In

terms of efficiency and time saved, the IC tags succeeded in producing a super

effect/productivity surge, as indicated in Fig. 5.1, which shows a comparison

of inspection times. What had taken 20 to 30 minutes for visual inspection

(with the aid of a delivery confirmation checklist) was reduced to only 2 to 3

minutes when IC tags were used to carry out the inspections.

Fig.

5.1 A comparison of Inspection-time (x

axis — Number of packages; y axis — Inspection times). Source: Japan

Automatic Identification System Association, “Findings of Trends in the

Automatic Identification Apparatus Market — Although down by 9% in 2007, a

slight increase is forecast for 2009”, “JAISA Bulletin,” 2009 Summer Edition,

Vol. 11/No. 2, 2009.

But

there was more to the super effect. It raised the sense of security, making it

less stressful for addressees and delivery workers. The reduction of stress for

patients, their families, and for people working in medical institutions,

particularly licensed nurses, is also priceless.

According

to the 2008 report compiled by the non-profit organization, Japan Council for

Quality Health Care (Chiyoda-ku, Tokyo, Chief Director, Tetsuo Ihara), there

were 1,440 medical accidents reported and a total of 220,000 medical incidents

reported as well. While medical incidents do not amount to medical accidents,

it is still extremely desirable to see the number of such incidents decrease

even if it is just by a little.

All

the more, when an error occurs, time is also lost to remedy the error, so this

is also a factor that cannot be ignored.

The

Pros and Cons of Two Methods

When

classifying RFID tags by power source, we can classify them into the passive or

active type. The former does not have a battery inside and operates by adjusting

electromagnetic waves emitted from reader-writers, so they are cheap and do not

require much maintenance. But their drawback lies in their short communication

range, extending only several meters.

The

latter, on the other hand, operates by drawing power from the battery in it, so

its communication range extends much further — no doubt a super effect.

However, its drawback is that it is limited by its battery life, thus requires

maintenance. Furthermore, it is relatively expensive.

When

examining the RFID tag by frequency band, another super effect becomes evident

here as well. In the case of the long wave frequency band (below 135 KHz), the

maximum possible communication range extends to 0.3 m. Although a relatively

long antenna is required, it is resilient to the impact of water and dust.

In

contrast, in the case of the microwave frequency band (2.45 GHz), the

transmission method changes from the electromagnetic induction method to the

Hertzian ray method and the communication range extends to 2 m, a one-digit

difference.

Although

a short-length antenna suffices, this has the drawback of being vulnerable to

the impact of water and dust.

Since

the RFID tag’s performance markedly varies by the power source it uses and by

its frequency band, it becomes necessary to make use of it in a way that

leverages its characteristic properties. However, compared to the conventional

bar code, the RFID is clearly the winner in many ways; in terms of recordable

data capacity, which is larger by two digits, amounting to several kilobytes;

in terms of its maximum communication range, which is comparably larger

(single-digit meters vs. dozens of centimeters); in terms of its ability to

make simultaneous readings of multiple sources; and in terms of its

penetrability (identifying individual units behind obstacles such as

cardboards).

[ BWW Society Home Page ]

© 2013 The Bibliotheque: World Wide Society