Fundamentals and Practices of Sensing Technologies

by Dr.

Keiji Taniguchi, Hon. Professor of

Xi’ an

Dr. Masahiro Ueda, Honorary

Professor, Faculty of Education and Regional Studies

Dr. Ningfeng Zeng, an

Engineer of Sysmex Corporation

(A Global Medical

Instrument Corporation),

Dr. Kazuhiko Ishikawa,

Assistant Professor

Faculty of Education and

Regional Studies,

[Editor’s

Note: This paper is presented as Part VIII of a series from the new book

“Fundamentals and Practices of Sensing Technologies”; subsequent chapters will

be featured in upcoming issues of this Journal.]

Chapter Four

Abstract for Chap. 4

Many measurement

technologies by means of the light have been developed and used practically for

many manufacturing industries. The principles of these technologies are very

simple usually, which are based basically on a light attenuation due to

absorption in the material and a light reflection due to scattering on the

surface. Another principle is based on an interference of the laser light,

which is successfully applied for a thickness measurement of the thin film and

coating.

The practical application

technologies using light attenuation were described in chapter 4, and those

using light reflection were described in chapter 5. These technologies were all

the results of our joint research works with many corporations.

The measuring technologies

using light have, generally, many advantages as follows.

(1) The

real-time measurement and monitoring can be realized because of the extremely

high propagation velocity (![]() m/s).

m/s).

(2) The

nondestructive measurement and detection can be realized since many light

receiving elements with very high sensitivity are now in the market.

(3) The

point measurement can be realized because the light can easily be focused into

the very small area.

(4)

The measurement without electro-magnetic noise can be realized.

(5) The

measurement at a far distance, i.e., the remote sensing technology, can be

realized, which is used successfully in many industrial plants such as a

nuclear power plant, for an example.

(6)

Optical path can easily be controlled by means of an optical fiber.

These advantages results

in the followings in the practical plants.

(i) The

measurements, which were hitherto done manually, can be replaced by these

technologies, that is, these makes a reduction of labor.

(ii

) The technologies make high quality manufacturing.

(iii)

The technologies economize the resources.

In this chapter, the

purposes, the principles, the methods and results of these technologies are

described. That is, a blood leakage sensor is described in 4.1, a dye color sensor

in 4.2, a thickness sensor for polyethylene foam sheet in 4.3, a weight density

sensor for row glass wool in 4.4, a rib form sensor for polyethylene sheet in

4.5, and a weight density sensor for glass wool pipe in 4.6.

4.1 Blood Leakage Sensor

4.1.1 Introduction

Recently, high

sensitivities are needed more and more in the field of medical electronics. One

typical application is a blood leak sensing system used in an artificial

dialyzer. A number of sensors such as a temperature sensor, flow rate sensor,

pressure sensor, negative pressure sensor and bubble sensor are used as well as

a blood leakage sensor in an artificial dialyzer. A number of dialyzing

treatments are normally needed in any one week for a patient suffering from a

kidney disorder, and therefore a blood leak could potentially cause fatal

damage, even if leakage in each dialyzing treatment is a very small amount. For

this reason numerous research projects have focused on a blood leak sensor1).

Most instruments used to

detect blood are based on an optical non-intrusive method using an infrared ray

or a visible ray from a semi-conductor laser or a diode. In the systems

presently used for the dialyzing treatment, an alarm is triggered only when

blood concentration exceeds a pre-set threshold level, and even then no

quantitative data of the total amount of blood leakage is provided.

Furthermore, patient's life is in danger during the treatment since the

sensitivity of the sensor in current use is too low to detect a minor leakage.

A patient can be released from the danger if a highly sensitive blood leak

sensor is developed which gives a linear sensitivity with concentration in real

time.

The main principle of

the present method is based on the light attenuation theory. Laser light is

attenuated by the presence of blood cells in the optical path in a container,

and thus the measurement of the light attenuation gives the concentration of

blood. The sensitivity and the accuracy may then depend on the sensitivity and

the stability of the intensity measurement system, and on the fluctuations of

the incident light, respectively. The sensitivity for blood detection of

present ranges between 0.01 and 0.001 in weight %2)(weight ratio of

blood to solution), which is too small for recent medical appliances.

The purpose of this

study is to propose a simple method for the improvement of both the sensitivity

and stability of blood concentration measurement, without using complicated

equipment to stabilize the laser output, and to describe the construction of a

practical sensor system.

4.1.2 Principles and Methods

Light intensity

decreases by absorption or scattering when it propagates in a non-transparent

medium. We can then determine the concentration or density of the medium by

measuring the light attenuation. Since the intensity decreases in proportion to

an optical path length through the medium (if the medium is homogeneous), the

path length is extended by the multi-reflection technique, using a pair of side

mirrors mounted on the test cell in order to enhance the sensitivity. The

present technique is effective for a higher sensitivity, however the use of a

narrow-beamed laser is necessary to avoid an over-enlarging beam size at the

exit of the cell.

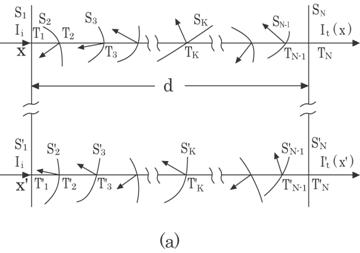

Figure 4.1 shows an

experimental setup. Laser light from a semi-conductor laser is divided into two

beams by a beam splitter, one is a reflected beam and the other a transmitted

beam.

Fig. 4.1 Experimental setup of the sensor. (Numerical

values in this figure are in mm ).

The

reflected beam directly enters a light power meter S1 and its power

is measured to provide the incident laser light level and is used for the

normalization of the attenuated light. The transmitted beam enters a cell in

which a test subject is filled and is led to a light power meter S2

after the multi-reflection on a pair of side mirrors inside the cell. The

attenuated power is measured by the meter S2 and is divided by the

power of the incident light given by S1. This normalization

automatically eliminates errors due to the unknown fluctuations in the

intensity of the incident beam. The multi-reflection extends the optical path

length and thereby increases the sensitivity. A semi-conductor laser with a

wavelength of 680nm has been chosen because it is reasonably priced and is easily

available for practical use. A physiological salt solution mixed with blood was

used as a test subject in order to evaluate the system sensitivity and

stability. The light attenuation of the laser was caused by scattering rather

than by absorption, since the laser light irradiates a red corpuscle.

The principle of the

method is also shown by a schematic diagram in Fig. 4.2. Although the light attenuation due to light

scattering in a weak solution has been discussed in detail in the literature3,4),

Lambert’s law of simple estimation of attenuation has been used, whereby the

light decreases exponentially with the path length in the medium. That is, the light

Fig. 4.2 Schematic diagram of the optics.

power

Io at a distance x from the entrance is related to the incident

light power Ii as

follows,

|

|

(4.1) |

where

![]() is an absorption

coefficient which depends only on the concentration or the density of the

subject n to be measured. Applying Eq. (4.1) to the present method (see Fig.

4.2), the light power I2 received in the second sensor S2

can be related to the light power I1, received in the first sensor S1

as follows,

is an absorption

coefficient which depends only on the concentration or the density of the

subject n to be measured. Applying Eq. (4.1) to the present method (see Fig.

4.2), the light power I2 received in the second sensor S2

can be related to the light power I1, received in the first sensor S1

as follows,

|

|

(4.2) |

|

where |

|

Where,

T and T' are the transmissivities of the beam splitter and the test cell glass,

respectively, r' and r are the reflexibilities of the beam splitter and the

side mirrors in the cell, respectively, p is a normalized optical path length

defined by p=x/L', where x shows a total optical path length. As is shown in

Eq.(4.2), the normalized output light power I2/I1 is

directly proportional to Io (x)/Ii. A logarithmic

expression of Eq.(2) is given as,

|

|

(4.3) |

An

absorbance defined by log(I2/I1) is thus directly

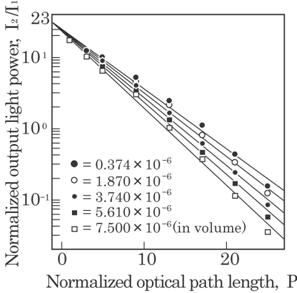

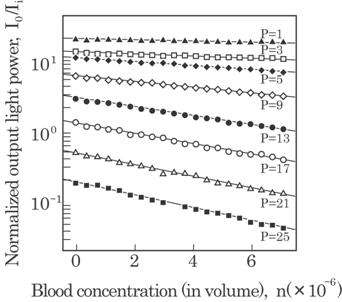

proportional to p. As shown in Fig. 4.3, the linearity between log(I2/I1)

and p was determined experimentally. The gradient of the straight

Fig. 4.3 Effect

of the optical path length, p, on the normalized output light power I2/I1

(in a logarithmic scale) for blood concentration, n.

line,

![]() , shows an apparent absorption coefficient

, shows an apparent absorption coefficient ![]() , from which an absorption coefficient

, from which an absorption coefficient ![]() can be calculated as

follows,

can be calculated as

follows,

|

|

(4.4) |

The

multi-reflections technique does not allow us to set the incident angle of the

laser beam to be normal to the mirrors in order to maintain its consecutive

reflections. This requires the term ![]() in Eq.(4.4), which

compensates for its effects on

in Eq.(4.4), which

compensates for its effects on ![]() . In this setup, the value of p in the equation is usually

larger than three and the magnitude of the effects of the shift is considered

to be less than 3%.

. In this setup, the value of p in the equation is usually

larger than three and the magnitude of the effects of the shift is considered

to be less than 3%.

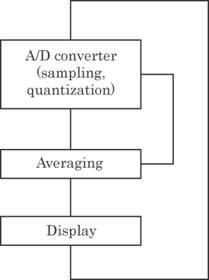

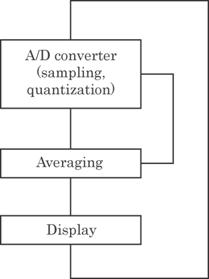

The measured data of the

light power I1 and I2 are processed by a data processing

system, shown in Fig. 4.4. The continuous analog signals of I1 and I2

are sampled, digitized and stored

in

a computer where the operation of I2/I1 is completed.

Results are given in the form of curves after smoothing. The resolution of the

data acquisition system is 12 bits and the sampling rate is about 800/s. One

data point in the figure is made by averaging 50 measured data, and then

requires 63 ms sampling time.

Fig. 4.4 Block diagram for the data acquisition system.

4.1.3 Experimental Results and Discussions

Before taking

experimental data, measurements were made in order to determine the system

parameters of the optical components, such as the transmissivity (T and T'),

and the reflection coefficient, (r and r'). The measurements gave T=0.93,

T'=0.90, r=0.90 and r'=0.04. This gives us T2T'/(r'r)=21.6, which is

in good agreement with the experimental data obtained at p=0 in Fig. 4.3.

First, the effects of

the optical path length were investigated. Experiments were carried out by

changing only the optical path length p, keeping the concentration and laser

output constant. Second, a series of experiments were conducted for various

concentrations and laser outputs. Results obtained are summarized in Figs. 4.3

and 4.5. The normalized output light power I2/I1 in the

logarithmic scale decreases linearly with the normalized optical path length p

as shown in Fig. 4.3, as well as with the concentration n, as shown in Fig.

4.5. The straight lines in Figs. 4.3 and 4.5 correspond to each normalized

optical path length and concentration, respectively, which were obtained by the

least squares method. It can be seen from these two figures that the normalized

output power decreases almost exponentially with the product of the normalized

optical path length p and the concentration n. Combining this fact with

Eq.(4.2) implies that the absorption coefficient ![]() is to be proportional

to n.

is to be proportional

to n.

Fig. 4.5

Effect of the blood concentration, n, on the normalized output light power

I2/I1 (in a logarithmic scale) for various optical path

length, p.

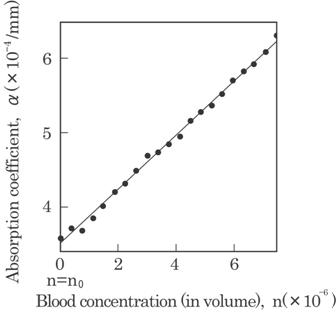

The absorption

coefficient ![]() for each concentration

n is shown in Fig. 4.6, which is determined from the gradient of the straight

lines in Fig. 4.3.

for each concentration

n is shown in Fig. 4.6, which is determined from the gradient of the straight

lines in Fig. 4.3.

As seen in this figure,

the absorption coefficient ![]() increases linearly

with concentration n as discussed above, and can be expressed as follows,

increases linearly

with concentration n as discussed above, and can be expressed as follows,

|

|

(4.5) |

where

c is a constant independent of concentration n and optical path length p. n0

is the absorption coefficient of the solution without blood and is estimated

experimentally to be n0=3.55![]() 10-4/mm, as seen in Fig. 4.6. The constant c can

also be determined experimentally by the gradient of the straight line in Fig.

4.6 and is calculated as 36.4/(mm

10-4/mm, as seen in Fig. 4.6. The constant c can

also be determined experimentally by the gradient of the straight line in Fig.

4.6 and is calculated as 36.4/(mm![]() concentration in volume). It depends only on the interaction

between blood and the laser, and therefore the wavelength of the laser plays an

important role in determining c.

concentration in volume). It depends only on the interaction

between blood and the laser, and therefore the wavelength of the laser plays an

important role in determining c.

Fig. 4.6 Effect of the blood concentration, n, on the

absorption coefficient, ![]() .

.

When red laser light is

used, as in this case, red corpuscles scatter the red light; the constant c is

mainly determined not by absorption but by scattering. If a blue laser is used,

on the other hand, the attenuation is caused by absorption. Combining Eq. (4.5) with Lambert's law

(Eq.(4.2)) results in the following Lambert-Beer's law5) which is

applicable for a diluted solution, as in our case,

|

|

(4.6) |

The

sensitivity is determined in practice by dividing an increment of the

normalized output laser power by the corresponding increment of the blood

concentration (n) in a solution, i.e.,

|

|

(4.7) |

Then

the relative sensitivity K divided by S(1) gives,

|

|

(4.8) |

The

sensitivity for p=1 corresponds to one of the conventional sensors. It is

apparent that the sensitivity of the present method is p times higher than that

of conventional sensors, although there is an advantage with the conventional

sensors in that they do not require an expensive laser (an economical laser

diode is quite enough for conventional sensors since the path length is

shorter).

The normalized optical

path length p can be multiplied by repeating the reflection on the pair of side

mirrors, if necessary, to increase the sensitivity. However, the maximum sensitivity is limited

by a cross sectional area of the laser beam after the multi-reflections because

the laser beams should not overlap each other on the side mirrors. The maximum

sensitivity can then be given by pmax=W'/d, where W' is a width of

the side mirrors as shown in Fig. 4.1, and d the laser beam diameter.

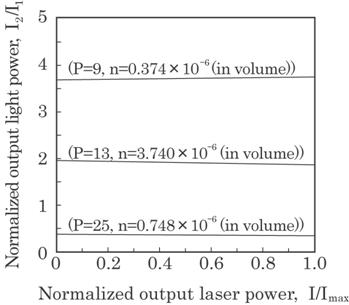

The normalized output

power I2/I1 is completely independent of the fluctuations

of the laser output power, as can be seen in Eqs. (4.2) and (4.3). This means

that a laser can be used without any complicated stabilizing equipment or

compensator for the light source, and is another distinguishing feature of the

present system, in addition to its high sensitivity. The independence of I2/I1

from the laser fluctuations has been confirmed by varying the laser output over

an intentionally wide range. The result is shown in Fig. 4.7. The normalized

output laser power is almost constant over the wide range of the laser output

I/Imax where Imax is the maximum output power of the

laser.

Fig. 4.7

Fluctuations of the normalized output power, I2/I1.

(The laser output power, I, is normalized by the maximum output power, IMAX.)

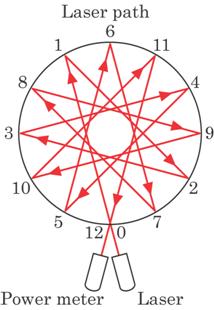

The cell configuration

used in this study is rectangular as shown in Fig. 4.1. However, a cylindrical

cell, as shown in Fig. 4.8, may be more practical from the view point of

commercial production. With this configuration, star-shape multi-reflections

can be applied and then both the inlet and outlet of the laser lights can

access the same window.

Fig. 4.8 A proposed cylindrical configuration for a

practical sensor.

In conclusions, the

following results were obtained.

(1) The

sensitivity of the sensor for blood leak detection has been improved by the use

of a beam splitter and a pair of side mirrors, which gives us about a few tens

of times higher sensitivity than conventional sensors on the market.

(2)

Further, the fluctuations of the laser power are completely compensated only by

using a beam splitter.

(3)

The practical sensor with the cylindrical cell has been proposed.

4.2 Dye Color Sensor

4.2.1 Introduction

In a dyeing process, it

is the most important to dye a cloth with consistent color. The tinting power

of dye, however, depends on its concentration, the material to be dyed, the

temperature of the dye, and other parameters. The concentration of each color

dye in a dye mixture decreases with time. The color dyes consumed must be replenished

instantaneously to maintain the same tint. A realtime measurement of a dye

concentration is then essential for this purpose.6)

A typical method now

used practically is spectrum analysis using a high power light source. This

method, however, is expensive and takes tens minutes to produce each

measurement because a precise measurement requires a high spectral sensitivity

and further dilution of the dye. A real-time measurement is thus practically

impossible.

The principle of a

real-time optical sensor for measuring dye concentration and the result of

preliminary experiments using a semiconductor laser have been reported

previously.7) In this section, the flexibility of a sensor system is

discussed from the viewpoint of practical use.

4.2.2 Principle and Method

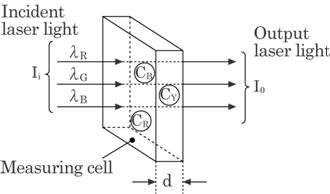

Figure 4.9 shows the

principle of the method. Laser light containing the three base colors

Fig. 4.9 Optical principle of the method. A part

of the incident light of three primary colors is

absorbed

in a dye mixture consisting of the three primary dye colors.

is

guided into a measuring cell. Part of the light is absorbed in the cell and the

rest passes through the cell and is received on a photodiode. The intensity of

the transmitted light can be expressed by Beer's law,8) if the dye

is diluted, as

|

|

(4.9) |

Where

Ii represents the power of the incident laser light, Io

the output power of the transmitted laser light, K is an absorption

coefficient, d is the cell width. The overall concentration, n, includes the

concentration of a dye, nx, and a reduced concentration, no,

taking account of the optical glass of the cell walls and additives for dyeing,

etc. As is shown in Eq. (4.9), the absorbance defined by log(Io/Ii)

is in direct proportion to nd and the absorption coefficient can then be given

as an absolute value of a gradient of the straight line absorption curve.

A dye can be mixed with

three base colors, i.e, red, yellow and blue base dyes. Unknown parameters to

be solved are thus the dye concentration of these three base colors. Three

pieces of information are therefore essential for the solution. These can be

obtained from the transmitted light power of three base colors. Light of

wavelength ![]() R=670 nm from a semiconductor laser and

wavelengths of

R=670 nm from a semiconductor laser and

wavelengths of ![]() G=515 nm and

G=515 nm and ![]() B=458 nm from a multiline Ar ion laser are used

for the light sources.

B=458 nm from a multiline Ar ion laser are used

for the light sources.

The absorption

coefficient depends mainly on the wavelength of the light ![]() (

(![]() R,

R, ![]() G,

G, ![]() B ) and the dye color C(

B ) and the dye color C(![]() R,

R, ![]() Y,

Y, ![]() B ). The absorption coefficient has then nine

components:

B ). The absorption coefficient has then nine

components:

|

|

(4.10) |

The

dye toning mixed with three base color dyes involves no chemical reactions. The

light attenuation is then proportional to the product of each attenuation by

the individual color dyes. The superposition principle for light attenuation,

therefore, can be applied to the present case where many color dyes are mixed

together. The assumption will be realized as discussed in section 4.1. The

transmitted light powers through the mixed dye are expressed as follows from

Eqs. (4.9) and (4.10):

|

|

|

where

|

|

(4.11) |

The

concentration of each dye color can then be obtained as,

|

|

(4.12) |

The

concentration sensitivity of the sensor, in other words, the resolving power of

the concentration, is defined by a small change of concentration due to a small

change of the light power. It can, therefore, be given as,

|

|

(4.13) |

Where

the negative signs in Eqs. (4.12) and (4.13) imply that an increase of light

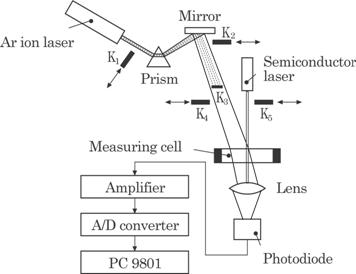

power corresponds to a decrease of the concentration. Figure 4.10 shows the

optical arrangement and the system of the sensor. Any wavelength of laser light

can be selected by properly choosing the shielding plates

Fig. 4.10 Optical arrangement and sensor system.

cell

is focused on a photodiode and converted to an electric signal. The signal is

amplified, sampled and digitized in 12 bits. The maximum sampling

frequency

of the data acquisition is limited to about 1 kHz by the A/D converter. The

digitized signal is used in Eq. (4.12) to calculate the concentration and the

results are displayed on the monitor. All the data used in this calculation are

obtained by averaging by 80 samples.

The dyes used in the

experiments are color indication numbers of C.I. Reactive Red 112, C.I.

Reactive Yellow 15 and C.I. Reactive Black 5. These are all ionized in water.

4.2.3 Results and Discussions

A. Results

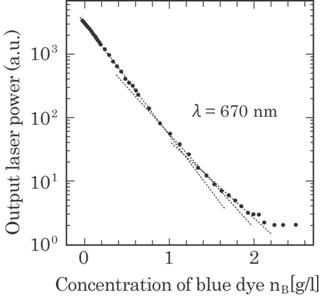

The output power of

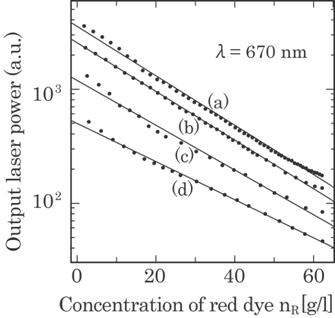

laser light was measured for a small change of the concentration. Figure 4.11 shows an example with a laser

light of wavelength ![]() R = 670 nm and blue color dyes. As seen in this

figure, the logarithm of output laser power decreases almost linearly

R = 670 nm and blue color dyes. As seen in this

figure, the logarithm of output laser power decreases almost linearly

Fig. 4.11 Output power of the laser light with a

wavelength ![]() R =670 nm passing through a dye solution with

various concentrations of blue dye.

R =670 nm passing through a dye solution with

various concentrations of blue dye.

with

an increase of dye concentration in a limited range of concentration. This indicates

the validity of the Lambert-Beer's law expressed in Eq. (4.9). The slope, -Kd,

has been calculated by the method of the least-squares fit. As seen in the

figure, the absolute value of the slope, Kd decreases slightly as the

concentration becomes high (the range of practical use). The small change of

slope would be one of the major reasons for error of this method.

The value of the

absorption coefficient in this case was calculated as K(![]() R,CB)=7.28 (g/l)-1cm-1

for d=0.55 cm. Similar experiments were run for all combinations of the three

base color lights and dyes. Table 4.1 shows all the data for K. The value

changes on a large scale, depending on the combination of laser light and dye

colors. This enables us to increase the sensitivity of the method to a level

which is high enough for practical use.

R,CB)=7.28 (g/l)-1cm-1

for d=0.55 cm. Similar experiments were run for all combinations of the three

base color lights and dyes. Table 4.1 shows all the data for K. The value

changes on a large scale, depending on the combination of laser light and dye

colors. This enables us to increase the sensitivity of the method to a level

which is high enough for practical use.

Table4.1 Absorption

coefficients for all combinations of three basic lights and dyes.

|

K( |

Measured

value g/(l*cm) |

|

K( |

0.0360 |

|

K( |

0.00412 |

|

K( |

7.28 |

|

K( |

109 |

|

K( |

2.72 |

|

K( |

34.8 |

|

K( |

61.3 |

|

K( |

27.4 |

|

K( |

20.8 |

Using the data in table

4.1 in Eq. (4.12), we obtain an expression for each concentration,

|

|

(4.14) |

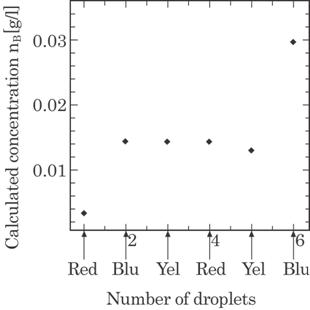

An experiment of

increasing each color dye successively was carried out to confirm the

reliability of the method. The dye concentration in the measuring cell filled

with water was successively increased by droplets of high concentration dye.

The output of the laser light was measured for each droplet and was used for

the calculation of the dye concentration. Figure 4.12 shows an example of the

calculated concentration for blue dye. As shown in this figure, the calculated

concentration of blue color dye changes only by the droplets of blue color dye.

The values of the change by both the droplets are about 0.009 and 0.016 g/l,

respectively, which are in good agreement with the real change of 0.013 g/l.

Fig4.12 Calculated concentration of blue dye for droplets of

each color of dye.

The resolving power of

the concentration, shown in Eq. (4.13), can also be obtained by using the data

in table 1, as follows,

|

|

(4.15) |

Thus

the resolving power depends directly on the resolution of the data acquisition

system for the output light power, ![]() Io/Io, which is given by the A/D

converter if the resolving power of the photodiode is sufficient. The total

range of light output is between 1 and 256, that is, the resolving power is

1/256, when the A/D converter with 8 bits is used. As an example, if the light

power changes for three base color of light are (

Io/Io, which is given by the A/D

converter if the resolving power of the photodiode is sufficient. The total

range of light output is between 1 and 256, that is, the resolving power is

1/256, when the A/D converter with 8 bits is used. As an example, if the light

power changes for three base color of light are (![]() Io/Io)R = 0.01, (

Io/Io)R = 0.01, (![]() Io/Io)G = 0.1 and (

Io/Io)G = 0.1 and (![]() Io/Io)B = 0.1 , the

resolving power of the concentration are calculated as

Io/Io)B = 0.1 , the

resolving power of the concentration are calculated as ![]() n R = -0.788 mg/l,

n R = -0.788 mg/l, ![]() n Y = -2.90 mg/l and

n Y = -2.90 mg/l and ![]() n B = -2.49 mg/l. These are in good agreement to

the experimental result in Fig. 4.12.

n B = -2.49 mg/l. These are in good agreement to

the experimental result in Fig. 4.12.

B Discussions

Firstly, the validity of

the superposition principle for the light attenuation is discussed as follows.

The reliability of this method is based on the superposition principle for the

light attenuation. This can be considered to be valid from the fact that the

dye mixing involves no chemical reaction. This has been examined

experimentally. Figure 4.13 shows an example of light attenuation through the

mixed dyes. The absorption coefficient K(![]() R,CR) is almost independent of the blue

dye. This validates the adaptation of the superposition principle. A small

change of K(R R, C R) will yield an error as discussed in

the next section.

R,CR) is almost independent of the blue

dye. This validates the adaptation of the superposition principle. A small

change of K(R R, C R) will yield an error as discussed in

the next section.

Fig. 4.13 Output power of the laser light with a

wavelength ![]() R =670 nm passing through a

R =670 nm passing through a

dye

solution with various concentrations of red color dye added with and without

blue color

dye: (a) without blue color dye, (b) with blue color dye of n B

=0.0625 g/l,

(c) n

B =0.125 g/l, and (d) n B =0.345 g/l.

Secondly, the error due

to a small change of absorption coefficient is discussed as follows. In figure

4.12, a difference between true and calculated values of concentration and also

the concentration change of blue dye due to the gradual addition of red dye and

yellow dye, are sources of error. The former was found to be about 3 mg/l and

the latter about 1 mg/l. Three major sources of error may be considered. The

first results from light fluctuation due to ambient light. However, the ratio

of the intensity of ambient light to the laser light has been made less than

1/1000 by shielding the light receiving system. The value is less than the

sensitivity and can be neglected. The second factor results from non-linearity

between log(Io/Ii) and (n) in Eqs. (4.9) or (4.11), as

shown in figure 4.11, when the concentration becomes high. We can, however, make

the apparent concentration low enough by using a thin cell width as discussed

in section 4.2.3 A. The last results from a small change of the absorption

coefficient due to the mixing of dye as described in section 4.1. This will be

a substantial problem for this method. A small change of concentration [![]() n] due to a small change of absorption coefficient [

n] due to a small change of absorption coefficient [![]() K] can be calculated from Eq. (4.12),

K] can be calculated from Eq. (4.12),

|

|

(4.16) |

where

[K]-1 shows an inverse of the matrix [K]. Thus, the change of dye

concentration may be the same order of the change of the absorption

coefficient.

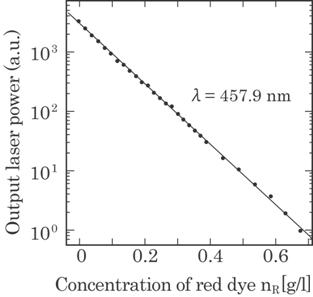

Thirdly, the

adaptability for practical use is discussed as follows. Figure 4.14 shows an

example of the output laser power for an extremely high absorption coefficient.

The measurable range of the concentration is between 0 and 0.63 g/l in this

case. However, we can measure higher concentrations by using a thinner cell

width d, because the absorption a coefficient K is the slope of a straight line

between ln(Io/Ii) and (nd) as seen in Eq. (4.9). That

Fig. 4.14 Output power

of the laser light with a wavelength ![]() B =458 nm passing through a

B =458 nm passing through a

dye solution with various concentrations of blue color dye.

is,

we can, apparently, make the concentration low by using thin cell width. As an

example, if a concentration range between 0 and 3 g/l is required, it can,

theoretically, be achieved only by making the cell width about d=1 mm. This

will, however, cause an error due to a concentration fluctuation in such a thin

cell width. One useful method to solve this problem may be to incorporate the

light emitter and receiver in one unit as a sensor head using an optical fiber,

as shown in Fig. 4.15. Practically only the sensor head is immersed in the dye

solution.

Fig. 4.15 Illustration of a proposed optical sensor head.

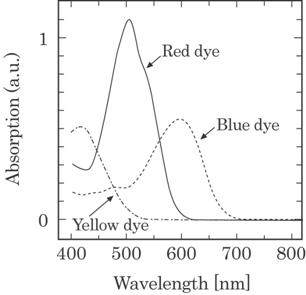

Lastly, the optimum

wavelength of the laser light is discussed as follows. Three base colors of

lights with the wavelengths ![]() R = 670 nm,

R = 670 nm, ![]() G = 515 nm and

G = 515 nm and ![]() B = 458 nm were used for the light sources in this

study. However, another wavelength may also be used effectively. A large

difference in absorbance, defined by log(Io/Ii), for each

wavelength and dye color is desirable for high sensitivity. Figure 4.16 shows

the absorption spectrum for three base color dyes. It may be concluded from

Fig. 4.16 that the desirable wavelengths of the laser lights are 430 nm, 460 nm

510 nm, 540 nm and 580 nm. Any three wavelengths in these five wavelengths,

e.g., 460 nm, 510 nm and 580 nm, will be sufficient for determining three

unknown parameters as discussed in this paper.

B = 458 nm were used for the light sources in this

study. However, another wavelength may also be used effectively. A large

difference in absorbance, defined by log(Io/Ii), for each

wavelength and dye color is desirable for high sensitivity. Figure 4.16 shows

the absorption spectrum for three base color dyes. It may be concluded from

Fig. 4.16 that the desirable wavelengths of the laser lights are 430 nm, 460 nm

510 nm, 540 nm and 580 nm. Any three wavelengths in these five wavelengths,

e.g., 460 nm, 510 nm and 580 nm, will be sufficient for determining three

unknown parameters as discussed in this paper.

Fig. 4.16 Absorption spectra of three base color dyes.

In conclusions, the

following results were obtained.

(1) The

sensor system can be used effectively for monitoring or detecting a small

change of dye concentration.

(2) The

concentration sensitivity of the method was about a few mg/l and may be

satisfactory for dyeing machines presently on the market.

4.3 Thickness Sensor for Polyethylene Foam Sheet

4.3.1 Introduction

Numerous optical sensors

have recently been developed in response to the fact that small-size

semiconductor lasers have become commercially available at a reasonable cost. 9)

Although the application of these sensors and lasers involves a wide

range of laws and theories in physics, Lambert's law is one of the most

frequently used to estimate light attenuation. The law was successfully

employed in a high sensitivity optical blood leakage detection system10)

and also in a dye concentration measurement system11).

In the present study,

light attenuation has been used to measure the thickness of sheets of

polyethylene foam and polystyrene. Polyethylene is widely used for a variety of

products such as bath mats, packing sheets for shipping and heat insulators for

building comfort. Polystyrene is mainly used for cups and hot food containers.

The thickness of the foam sheet is important to the makers from the viewpoint

of standardization of manufacture. The major difficulty in thickness

measurement of foam sheets is caused by the heterogeneous cell structure of the

foam, which yields enormous fluctuations in the measured data depending on the

measurement technique and on the sampling locations. An averaging method has

been adopted for solving this difficulty and enables us to determine the

thickness with good accuracy. A complete measuring system has also been

constructed in order to demonstrate the suitability of the present method for

industrial use.

4.3.2 Principle and Method

A. Principle

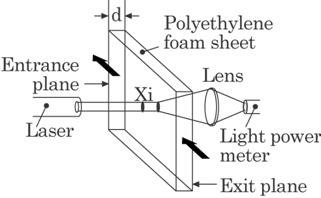

Figure 4.17 shows a

fundamental illustration of a light attenuation process. Polyethylene

or

polystyrene foam consists of small cells filled with air. The light is

scattered at each cell wall as it passes through the foam. The transmitted

light intensity, It, is then given by the multiplication of the

transmittance, Tk, on each cell surface in the measuring optical

path, as follows12):

|

|

(4.17) |

Where

Ii is the input light intensity and N the number of the cell surface

along the optical path. In particular, T1 shows the transmittance on

the surface of the foam sheet. The transmittance, Tk(k=1,2, ![]() N), and the total number, N, are then a function of an

irradiated position x, as shown in Fig. 4.17(a). Thus, the output, i.e.,

transmitted light intensity, depends on the position.

N), and the total number, N, are then a function of an

irradiated position x, as shown in Fig. 4.17(a). Thus, the output, i.e.,

transmitted light intensity, depends on the position.

Fig. 4.17 Light attenuation in a foam sheet from

the microscopic viewpoint (a), and from the macroscopic viewpoint (b).

We expect, however, that

the output light intensity after passing through an optical path d, Id,

follows Lambert's law5) if a sample is uniform, as given by

|

or,

|

(4.18) |

where

![]() is an absorption

coefficient. This is an approximate expression for light attenuation form a

macroscopic viewpoint. That is, the output intensity, Id, is

considered to be the mean value of It (x) for many sampling points

around the measuring point.

is an absorption

coefficient. This is an approximate expression for light attenuation form a

macroscopic viewpoint. That is, the output intensity, Id, is

considered to be the mean value of It (x) for many sampling points

around the measuring point.

As is shown in the

following section, the mean values of T(x), <T(x)>, at each measuring

point x, are approximately equal and we can then assume:

|

|

(4.19) |

Using

Eqs. (4.17) and (4.18), and the relation given in Eq. (4.19), we obtain the following

relation:

|

|

(4.20) |

Equation

(4.18) gives us information on the thickness and Eq. (4.20) on the cell

density, N/d or the cell transmittance.

B. Method

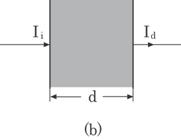

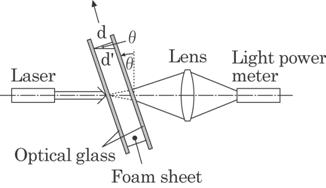

Figure 4.18 shows the

experimental set-up for a measurement. Laser light of wavelength 670 nm from a

semiconductor laser passes through a polyethylene sheet. The transmitted light diverges by scattering

in the foam and is focused on a light meter. The light power, Id, is

processed by the data acquisition system shown schematically in Fig. 4.19.

Fig. 4.18 Fundamental optics of the experimental set-up.

Fig. 4.19 Block diagram of the data acquisition and

processing system.

The continuous analog

signals of Id are sampled, digitized and stored in a computer

memory. Results are given in the form of curves after smoothing. The resolution

of the data acquisition system is 12 bits and the sampling rate is about 400Hz.

Figure 4.20 shows a

particular experimental set-up to measure the effect of cell structure on the

transmittance, e.g., light attenuation. The polyethylene foam sheet is placed

between a pair of transparent optical glass plates, slightly inclined to the

normal to the laser beam. The thickness of the sandwiched foam sheet, d, is

changed by compressing the glass plate. The optical path length through the

sheet foam is thus changed by the compression of the glass plate or its

inclination.

Fig. 4.20 Optics to measure the effects of

compression and inclination of a semi-transparent foam sheet.

4.3.3 Results and Discussion

A. Results

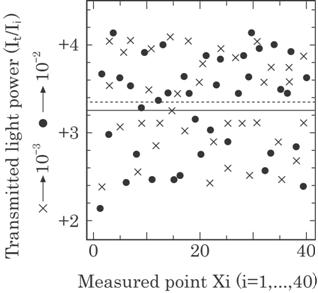

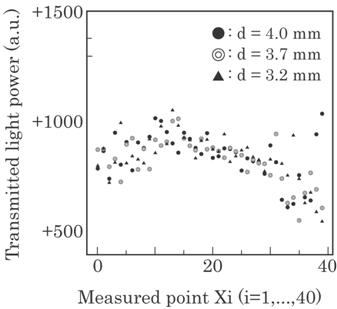

Figure 4.21 shows an

example of the transmitted light power at each measuring point. As shown, each

data point differs to a great extent from the mean value, the range of which

reaches

70%. This is attributed to the difference of total transmittance, T(x), along

each optical path, as shown in Fig. 4.17(a), T1 may be the major

factor. The difference can, however, be reduced by smoothing, i.e., averaging.

Two technical methods, both of which are based on the same principle, are

available for this smoothing. One is to enlarge the spot size of the laser

irradiation. This method, however, necessitates the use of a large focusing

lens and further to cut an ambient light off to a very small amount. The other

method, used in this study, is to make many measurements around a small region.

Fig. 4.21 Transmitted light power at each point.

(![]() )

d1=2.76 mm; (

)

d1=2.76 mm; (![]() ) d2=5.58 mm; (

) d2=5.58 mm; (![]() ) Mean

) Mean

value of

3.35![]() 10-3 for d2=5.58 mm; (-) Mean value of

3.24

10-3 for d2=5.58 mm; (-) Mean value of

3.24![]() 10-2 for d1=2.76 mm.

10-2 for d1=2.76 mm.

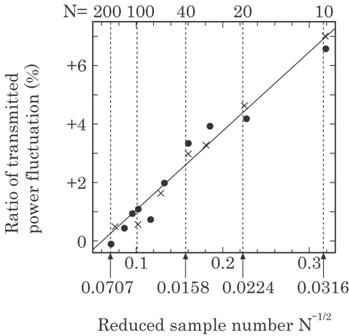

The smoothing effect is

shown in Fig. 4.22. As shown, smoothing over 80 points restricts the

fluctuation of the mean value within a range of 1%. All the data except one

example given in Fig. 4.21 were averaged over 80 points.

Fig. 4.22 Relation between the transmitted light

power fluctuation (%) and the reduced

sample

number.

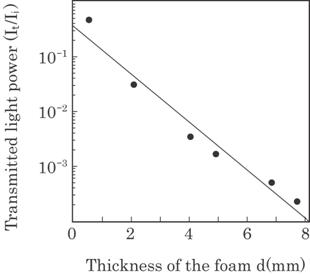

Fig. 4.23 shows an

example of the relation between transmitted light power and foam thickness. It

can be seen that the transmitted light power decreases exponentially with the

Fig. 4.23 Relation between the averaged light power and the

foam thickness d.

thickness.

A straight line can be obtained by the method of a least mean square fit. The

gradient of the straight line gives the absorption coefficient, ![]() , in Eq. (4.18). The value depends only on the property of

the material used. A value of the thickness, d, has to be known for a

determination of absorption coefficient,

, in Eq. (4.18). The value depends only on the property of

the material used. A value of the thickness, d, has to be known for a

determination of absorption coefficient, ![]() , and should be measured by another method, e.g., the gage

method.

, and should be measured by another method, e.g., the gage

method.

In applying the method

practically, the absorption coefficient, ![]() , has to be determined repeatedly for each product.

, has to be determined repeatedly for each product.

B. Discussion

The effect of the cell

structure on the transmitted light power was examined using the optical

arrangement shown in Fig. 4.20, where the optical path length is changed. The

number of cell surfaces remained constant when we compressed the foam sheet and

so the transmitted light power may be assumed unchanged.

Figure 4.24 shows an

example of the effect of sheet compression on the transmitted light power. As

expected, the transmitted light power was almost the same for each compressed

foam sheet, i.e., d=3.7 mm and d=3.2 mm. This implies that each cell surface

has an equal

Fig. 4.24 Transmitted light power under

squeezing. (![]() )

Normal foam sheet; (

)

Normal foam sheet; (![]() ),

(

),

(![]() )

)

squeezed

foam sheets. Each datum is an averaged value over 80 points in the

vicinity

of each other.

transmittance

and that the total transmittance through the optical path depends on the

transmittance of the material and the number of cell surfaces. That is, the

assumption in Eq. (4.19) is justified.

The optical path length

increases when the normal of the foam sheet is inclined to the optical axis,

and then the transmitted light decreases. In this case, the foam thickness, d,

has to be replaced by (d/cos![]() -1), as shown in Fig. 4.20. Figure 4.25 shows the effects on

the transmitted light power, where the abscissa shows reduced inclination,

1/cos

-1), as shown in Fig. 4.20. Figure 4.25 shows the effects on

the transmitted light power, where the abscissa shows reduced inclination,

1/cos ![]() -1. This figure also implies the validation of Eq. (4.19).

-1. This figure also implies the validation of Eq. (4.19).

The accuracy of this

method depends on the linearity between the thickness and the decrease in the

transmitted light power, as shown in Eq. (4.18). The light fluctuation due to

ambient light introduces errors. It is very difficult to discriminate laser

light from ambient light, but it is easy to reduce the effect to ambient light.

Two methods are available. One is to use a pulsed laser of high peak power, but

this is too expensive for our purpose. The other is to cover the laser light

receiving system with a proper cylinder case. This can reduce the ambient light

power below 0.05% of the maximum power of the transmitted laser light.

Fig. 4.25 Effect of inclination on the

transmitted light power. The ordinate shows the light

power

normalized by the one for ![]() =0 and the abscissa the reduced inclination

=0 and the abscissa the reduced inclination

(1/cos![]() -1).

-1).

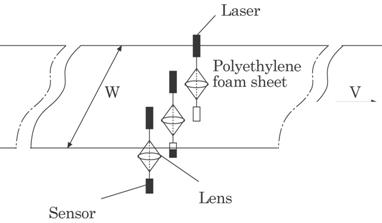

4.3.4 Practical Applications

In practical foam

production, molten polyethylene in an extruding machine is squeezed out from a

circular arc air nozzle and is formed to a sheet. The circular nozzle is

divided into a few small portions, each of which has a nozzle aperture which

can be controlled independently. The speed of output of the sheet is about 1-2

m/s and its width is about 2 m. The usual gage method of picking up contact

elements is therefore difficult. Furthermore, it can only measure the thickness

at both edges of the sheet. On the contrary, the present method may solve the

above disadvantages simultaneously. Figure 4.26 shows an example of the

practical optical set-up for the measurement. One optical sensor is desirable

for each nozzle, where a sensor signal is processed to control the nozzle

aperture. All the sensor signals from each sensor are processed on the computer

simultaneously. The thickness of each portion along the width can thus be

adjusted to the same thickness.

Fig. 4.26 Optical system for practical use.

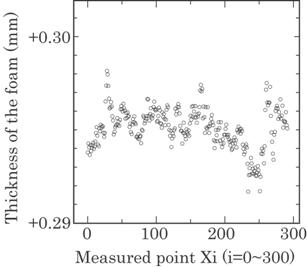

Figure 4.27 shows an

example of the results. The sampling rate of this system was about

Fig. 4.27 Thickness of the polyethylene foam

sheet measured in the manufacturing process. Each datum was plotted at

intervals of 3 m and total length was 300 m.

400

Hz. The production speed of the foam sheet was 1.5 m/s. As discussed above, one

datum was given as the average of 80 points and then the average along a

0.3(=1.5*80/400) m length. The spot size of the laser was about 5 mm in

diameter at an irradiated surface and then each sampling point slightly

overlapped each other. The deviation of the thickness was found to be within

0.01 mm over 90 m from this figure. The deviations on other portions in the

width direction were kept within this range.

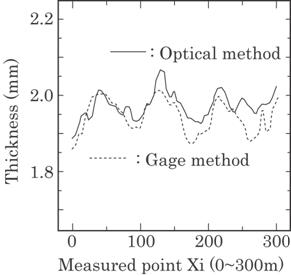

Figure 4.28 shows another

example of the measurement. This is a result given by the system developed for

the precise measurement for a food container. The foam sheet for a food

container was produced with relatively slow speed of about 10 cm/s. Each

sampling point was

Fig. 4.28 Thickness of the polyethylene foam

sheet measured in the manufacturing process.

overlapped

close together. That is, each datum was not an average over totally different

points but over locally common points. The result by the usual gage method is also

shown for the comparison. Both results agreed quite well within a deviation of

20![]() m. From the result, the error of the method in this study is

supposed to be within a few tens of micrometers.

m. From the result, the error of the method in this study is

supposed to be within a few tens of micrometers.

In conclusions, the

following results were obtained.

(1) The

light attenuation was used in this measurement, and averaging enabled us to

determine the thickness precisely in spite of large fluctuations in measured

data due to the heterogeneous structure of the sheets.

(2)

Automatic thickness control can be accomplished in the manufacturing of these

sheets.

(3)

The error of this measurement is a few tens micrometers.

4.4 Weight Density Sensor for Row Glass Wool

4.4.1 Introduction

The glass has recently

been used more and more, in particular owing to the advancement of

manufacturing technique of high purity and glass fiber. An optical fiber in a

communication service is the representative example. The other examples are

processed goods of glass wool such as a dust proof paper, separator to insulate

electric current in a battery and heat-resisting and sound-resisting mats used

mainly in a car and a building. An efficiency of the finished goods, i.e.,

homogeneity in particular, depends on a manufacturing process, mainly on a

weight density of raw glass wool.

The weight density may

be measured by an attenuation of a sound wave and electromagnetic waves such as

microwave and light wave through the raw glass wool. A source of the microwave

will, however, be rather expensive for an industrial use. The sound wave will

have a troublesome problem of noise when it is used in the factory. That is, a

signal obtained by the sound wave of proper frequency for the measurement will

include rather large noise produced in the factory. The noise will usually include

all over the frequency range and we can not distinguish between signal and

noise. On the contrary, we can, easily screen the noise light from the signal

light.

We have previously

reported a new method to monitor the thickness of a semitransparent foam sheet

in realtime using a laser light13). The principle of the method is

based on the light attenuation through the foam sheet. The method can also be

applied to glass wool weight density since the thickness is directly

proportional to the weight density if the foam sheet is homogeneous. It was

very simple and was found to be effectively applied for industrial use. It has,

however, a drawback to scan the laser beam to examine all the area because an

intensity of the laser is rather small. The raw glass wool usually produced is

rather thick and then light attenuation and divergence through it become rather

large. It, therefore, requires a focusing lens for a transmitted laser light

due to a divergence through the glass wool. This prevents use of laser light as

a light source and photodiode as a light receiver.

In this section, we

propose a practical method to overcome these drawbacks, that is, high intensity

white light is used as a light source and a large scale solar cell as a light

receiver.

4.4.2 Method and System

The fundamental

principle of the method is based on the light attenuation theory12,13).

But the method in this paper is different from the previous one in two points

from a practical point of view. One is to use a white light with high intensity

instead of laser light. This enables us to use solar cell as a light sensor and

the method to be effectively applicable for high attenuation object. The other

is to use a solar cell as a light sensitive sensor instead of photodiode. The

solar cell, in itself, is not a light sensitive sensor but a converter from a

light power to an electric power. The solar cell has a large dimension as

compared to the photodiode. It makes, therefore, a spatial averaging over the

cell dimension without scanning the area. It can, further, measure a rather

diverged light through the thick semitransparent object such as glass wool

without focusing lens. The solar cell has, however, such disadvantages as a low

sensitivity to the light and incomplete characteristics in each cell. The low

sensitivity can be solved by using an intense light source and a large scale

cell. The incomplete characteristics can be compensated by using an amplifier

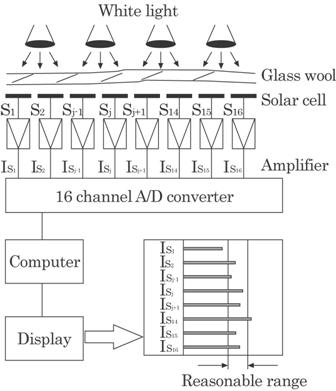

to each solar cell independently as in Fig. 4.29.

Figure 4.29 shows a

whole system used in a manufacturing plant. Four high intensity white light

sources with each output of 500 W were used. These were placed at a distance

about 800 mm from a top of the glass wool to illuminate it uniformly as

possible as we can. Sixteen solar cells of each dimension 90mm![]() 230mm were used as the light receivers. These were placed at

about 30mm from the bottom of the glass wool to receive the transmitted light

directly and at the same time to avoid an attachment of the glass wool to the

cells.

230mm were used as the light receivers. These were placed at

about 30mm from the bottom of the glass wool to receive the transmitted light

directly and at the same time to avoid an attachment of the glass wool to the

cells.

Fig. 4.29 Illustration of the system.

The outputs of each

solar cell are amplified independently to compensate the output characteristics

of each solar cell and the lack of uniformity of irradiated light intensity on

the glass wool. That is, all the outputs of each solar cell are adjusted by

each amplifier to show the same value under the same weight density. These

amplified signals are then digitized by an A/D converter, averaged by a

computer and displayed on the monitor as shown in Fig.4.29. Sampling time ts

of the data acquisition is about ts= 0.1s and a processed data is

obtained at an interval Td= 1s in this case. That is, one data is

obtained as a 10 times averaging ( n = Td/ts, n; times

for averaging). The data can, however, be obtained at an arbitrary time

interval by the computer control. The production speed v of the glass wool is

about v = 250mm/s and then the processed data on the monitor is a mean value

for an area of 90mm![]() 250mm(= 25mm

250mm(= 25mm![]() 10). Strictly speaking, the averaging area is not so as

discussed in 4.43.

10). Strictly speaking, the averaging area is not so as

discussed in 4.43.

Lamber's law5),

which gives a relation between input Ii and output Io

light intensity, can be expressed as follows,

|

|

(4.21) |

where

D shows the glass wool weight density of the corresponding area and k an

absorption coefficient which depends on a property of the material. Thus, a

natural logarithms of the light intensity ratio is in direct proportion to the

weight density. The weight density of a practical product has nearly a constant

value, D=Dc, as shown in Fig. 4.29. In this case, a small increment

in density, ![]() Dc, may causes a small decrease in output light

intensity,

Dc, may causes a small decrease in output light

intensity, ![]() Ioc, using a first approximation as follows,

Ioc, using a first approximation as follows,

|

|

(4.22) |

This

shows that a small increment in the weight density from about a constant

density Dc is in direct proportion to a small decrease in the output

light intensity Ioc. The error of this approximation is only 2% for ![]() Dc

Dc![]() 0.2, since e0.2-(1+0.2) = 0.021. We use Eq. (4.22)

in a practical application of this system.

0.2, since e0.2-(1+0.2) = 0.021. We use Eq. (4.22)

in a practical application of this system.

4.4.3 Result and Discussion

The system has

successfully been used in a manufacturing plant of Japan Inorganic Chemistry

Co. Ltd. at Yuki Factory, ![]() 25%.

25%.

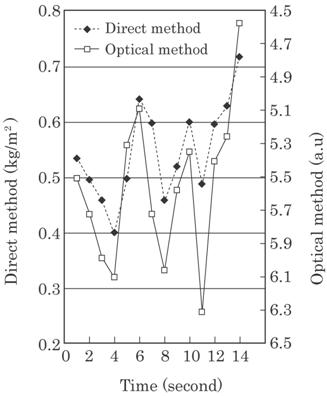

Figure 4.30 shows an

example of the light intensity for one channel (by optical method) and the

measured weight density of the corresponding area (by direct method). Thus, the

tendency between both values by optical and direct methods with time flight is

found to be coincide perfectly with each other. All the data for 16 channels

have similar tendency.

Fig. 4.30 Weight density of the raw glass wool by both

direct and optical methods.

Figure 4.31 shows both

change rates by optical and direct methods in Fig. 4.30 to discuss the validity

of this method. The optical change rate is different about 10% from the direct

one.

This

may be considered as an error of this optical method. It is not, however,

necessarily so since a cutting the raw glass wool into pieces is very difficult

and then the measured value itself includes some errors. The set point of this

weight density is 500 g/m2 in manufacturing plant. The averaged

values, however, is 547 g/m2 which is larger about 10% than that of

the set point. This is indispensable to assure the finished good's efficiency,

i.e., adiabatic and sound-proofing effectiveness. It was further found that the

change rate of optical value is always smaller than that of measured value.

This is unavoidable to this method which uses large scale photo-receiver for

measuring a light intensity through a moving object.

Fig. 4.31 Change rate of the weight density by

both direct and optical methods. Optical values are reversed.

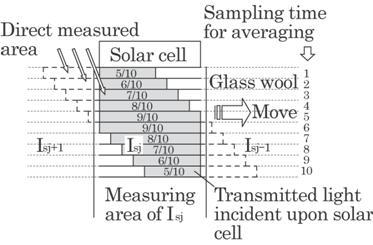

Figure 4.32 shows this

principle. A piece of raw glass wool used for both measuring methods has a

dimension 9cm![]() 25cm. The solar cell having a dimension of 9cm

25cm. The solar cell having a dimension of 9cm![]() 23cm receives transmitted light corresponding to that area on

the glass wool. The glass wool moves

23cm receives transmitted light corresponding to that area on

the glass wool. The glass wool moves

Fig. 4.32 Principle of the received light

intensity on the large scale solar cell from the measuring area of the raw

glass wool.

25mm

between each data sampling and 25cm between each processed data since it is

obtained by a ten times averaging of the sampling data. In the central region

of the piece, i.e., regions 5 and 6 of sampling time for averaging, the solar

cell receives 9/10 of the transmitted light from the measuring piece. But it

receives only a 5/10 from the measuring piece and a remaining part from the

adjacent piece as shown in this figure. The optical value, therefore,

shows

the results obtained from wider region than that of measuring piece. This is a

reason for the difference between measured and optical change rates. The

difference may be reduced slightly by taking a weighted mean in place of an

arithmetic mean used in this experiment. The method of a weighted mean can not,

however, settle the problem radically because the measured region for both

methods of optical and direct measurement is essentially different.

Errors within plus or

minus 10 % or so exist in our optical system as seen in Fig. 4.31. It can be,

however, decreased in accordance with 1/(N)1/2 from the theory of

error13), where N is an averaging times. To do this effectively, a

smaller size photo-receiver than that used in this system must be used for the

same measuring area and the sampling time of data acquisition must be reduced

considerably. This can effectively make N large without the essential problem

caused by using large photo-receiver. However, this inversely leaves a strong

point of using large scale solar cell described in chapter 1. In conclusion, we

must find out a meeting point between them.

The optical method in

this study can only measure a relative value of the weight density. The

correction is required to obtain an absolute value from the optical value. For

this purpose, the absorption coefficient k in equation (4.21) has to be

determined from some light outputs for some known weight densities, for

examples, 400 ,500 and 600 g/m2.

In conclusions, the

following results were obtained.

(1) The

optical method using a white light and a solar cell as a light source and light

receiver can be used successfully for the weight density measurement of raw

glass wool in real time.

(2)

The mean error of the method is about 10%.

(3) The

system has now been successfully used in a manufacturing plant to find out

inferior goods of more or less than 25% weight density. It can further be

applied for production process.

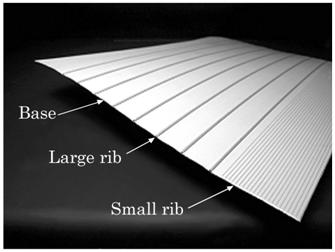

4.5 Rib Form Sensor for Polyethylene Sheet

4.5.1 Introduction

Polyethylene sheet has

been widely used in industry. For example, it has been used in a battery as an

impregnation material for sulfuric acid. For such applications, ribs are

usually constructed on the sheet surface to control the amount of sulfuric

acid; the amount of electricity generated and the life time of the battery are

determined by the size of the rib. The size of each rib, i.e., width and

height, and the separation between ribs have been measured by microscopic

observation in off-line. It is very laborious and time-consuming process.

Recently sensors were

introduced to this problem.14~16) They are costly, however, and

difficult to use in a manufacturing plant in real time; they can only measure a

surface contour of the sample in off-line.

In this section, we propose

an optical method and present a measuring system for the size of rib, the

separation between each rib, and the thickness of the polyethylene sheet.

4.5.2 Method and System

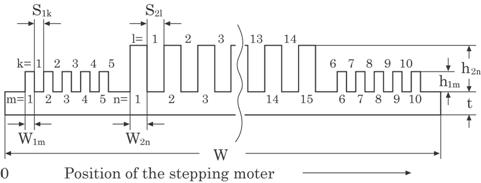

Figure 4.33 shows a

photograph of polyethylene sheet used in a battery, and Fig. 4.34 shows a

cross-sectional scheme of it. The sheet size is usually about 12cm in width,

about

Fig. 4.33 Photograph of the polyethylene sheet with ribs on

the surface.

20cm

in length, and few tenths mm in thickness; ribs have been constructed on it.

Each rib size is a few tenths mm in width and a few tenths mm in height, and

the separation of it is about 10 mm. The purpose of this study is to measure

the following parameters concerning

Fig. 4.34 Cross sectional view of the sheet.

the

polyethylene sheet; (i) the whole width W, (ii) the thickness t, (iii) the rib

separation S, (iv) the rib width w, and (v) the rib height h (see Fig. 4.34).

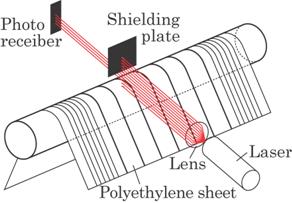

Figure 4.35 shows a

principle of the method, which is based on the fact that a probing light

intensity, i.e., a transmitted light intensity, is linearly proportional to the

gap between the shielding plate and the polyethylene sheet with a rib. A light

sheet was used as a probing light.

Fig. 4.35 Principle of the method.

A semiconductor laser

was used to form a thin light sheet, which was essential for measuring a small

width precisely.17) In this case, the width of the laser sheet

should be small enough compared to the width of the rib in order to obtain a

sharp edge of the rib, which determines the measuring precision of the width. A

light sheet of about 1/10 mm in width was used in this experiment. A silicon

photodiode was used as a light receiver. The height and width of the rib, the

separation between each rib, and also the thickness of the polyethylene sheet

can then be measured by scanning a sheet laser as shown in this figure. In this

experiment, a light source and a light receiver were fixed and a sample was

mounted on the stepping motor as shown in figure 4.37.

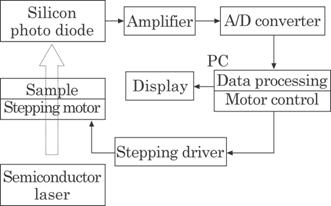

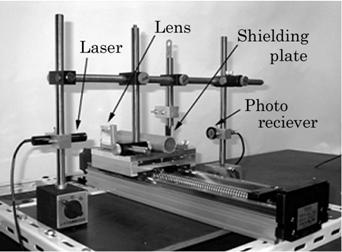

Figure 4.36 shows a

block diagram of the entire system, and figure 4.37 shows a photograph of the

equipment made for the experiment. The laser light intensity received on the

silicon photodiode was amplified to a level acceptable for A/D input, in this

case 5 V, and was digitized by a 12-bit A/D converter, i.e., 1~4096 steps. The

digitized intensity was then used for the calculation of rib size, separation

between ribs, and thickness of the polyethylene sheet.

Fig. 4.36 Block diagram of the whole system.

Fig. 4.37 Equipment of the system.

A control signal for

driving the stepping motor was about 100 Hz with a rectangular wave and was

synchronized with the received laser signal to measure the widths of the rib

and polyethylene sheet, and the separation between ribs. One cycle of the

rectangular wave drives the motor 1/100 mm and then the positioning precision

of this measurement is 1/100 mm. Then 120 seconds are required to scan the

entire sheet with the width of 120 mm. The sampling frequency of data

acquisition is about 1 kHz; 10 data are obtained within one cycle and a mean

value of these 10 data is used as a measured value of the received light

intensity. This averaging will reduce the measuring error due to a fluctuation

of the scattered light on the surface of polyethylene sheet. Figure 4.39 shows

these measured values at each position.

The error comes from a

change in the received light intensity due to laser output, and dust on the

light source and light receiver when the system is used in the factory. The

problem could, practically, be solved as follows. The measured intensity I is

normalized by light intensity I0 through a constant gap g0,

in this experiment g0=0.5 mm; the normalized light intensity, I/I0,

is used as data. The calculation was made by means of software.

4.5.3 Experimental Results and Discussions

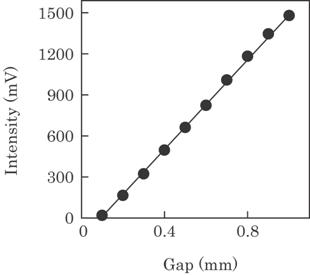

The intensity of a laser

beam usually has a Gaussian distribution in a radial direction. This causes a

measurement error since a linear relation between the transmitted light

intensity I, and a gap g, is obtained under condition that the intensity

distribution along the laser sheet is constant. This can be solved by using a

central portion of the laser beam as a probing light. Figure 4.38 shows the

relation between the transmitted light intensity I, and the gap g. As shown in

this figure, the transmitted light intensity linearly increases with an

Fig. 4.38 Relation between transmitted light intensity I and

a gap g.

increase

of the gap.

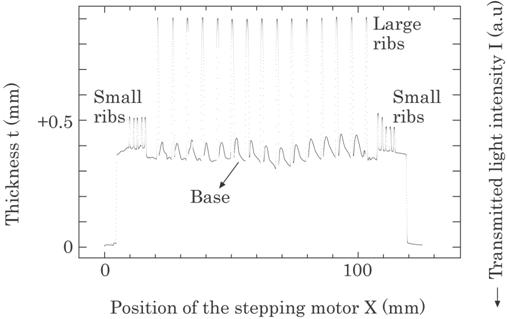

Figure 4.39 shows

received light intensity versus position on the polyethylene sheet. Each datum

is a mean value of 10 sampling data as mentioned in section 4.5.2. In this

figure, the top and bottom were inverted to give the thickness of the

polyethylene sheet and the height of the rib directly.

Fig. 4.39 Transmitted light intensity across the

sheet surface. In this figure, the top and

bottom of

the light intensity are inverted to give a thickness directly.

A separation s, a rib’s

width w, a sheet’s thickness t, and a rib’s height h are obtained from this

figure. The problem is, however, caused on the determination of s and w because

the intensity distribution is not rectangular but sine-like configuration.

These values can, however, be determined by the following two methods. One is

to find the position of an abrupt change of the transmitted light intensity.

That is, the width can be measured as a distance between the positions of an

abrupt decrease and the abrupt increase of the intensity due to a rib. The

other is to find out the position of the threshold light intensity; the space,

in which a light intensity is below the threshold level, is the rib's width. It

seems that the latter method is simple to use. However, it was found from the

experiments that the former method has three main advantages over the latter

method. Firstly, it is easy to find out the abrupt change of the light

intensity automatically by the use of software; on the contrary, it is

difficult to find out the threshold level automatically for all kinds of

polyethylene sheet. Secondly, the latter method involved an error due to the

large change of the base thickness; it was indistinguishable between ribs and

base, in other words, threshold level can not be determined. However, the

former method has no error due to such change. Finally, the width obtained by microscopic

observation agreed better to the one by the former method than that by the

latter method; the width obtained by the latter method was about 10 % smaller

than that by microscopic observation. Thus the former method was used in this

experiment.

The thickness of the

polyethylene sheet t, and the height of the rib h, can be determined by the

amount of the intensity decrease. Thus, all the information on the sheet can be

obtained automatically within 120 seconds.

Table 4.2 shows these

values obtained from figure 4.39. Each symbol of s1, s2,

h1, h2, w1 and w2 is expressed with

suffix number k, l, m and n which correspond to each dimension from left to

right as shown in Fig. 4.34.

Table 4.2

Results for the widths of polyethylene sheet and rib, W and w, the

thickness of polyethylene sheet t, the separation s, and the height of the rib

h, which are shown schematically in figure 4.34.

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

S1j |

1.61 |

1.57 |

1.66 |

1.56 |

4.81 |

4.58 |

1.61 |

1.60 |

1.63 |

1.56 |

|

S2j |

5.84 |

5.91 |

5.87 |

5.94 |

5.88 |

5.89 |

5.82 |

5.99 |

5.89 |

5.99 |

|

h1k |

0.13 |

0.12 |

0.12 |

0.15 |

0.16 |

0.14 |

0.13 |

0.12 |

0.11 |

0.11 |

|

h2l |

0.48 |

0.48 |

0.48 |

0.47 |

0.47 |

0.47 |

0.47 |

0.47 |

0.47 |

0.46 |

|

w1m |

0.30 |

0.26 |

0.26 |

0.36 |

0.42 |

0.30 |

0.30 |

0.34 |

0.26 |

0.30 |

|

w2n |

0.72 |

0.62 |

0.70 |

0.62 |

0.70 |

0.62 |

0.72 |

0.66 |

0.68 |

0.62 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

12 |

13 |

14 |

15 |

|

|

|

|

|

|

S2j |

5.96 |

5.86 |

5.87 |

5.94 |

|

|

|

t=0.32

(mm) |

||

|

h2l |

0.47 |

0.47 |

0.48 |

0.47 |

0.46 |

(mm) |

W=115

(mm) |

|||

|

w2n |

0.56 |

0.72 |

0.62 |

0.52 |

0.52 |

|

|

|

|

|

In conclusions, the

following results were obtained.

(1) The

system consists of a sensor head including laser and silicon photo diode, a

scanning system of the laser head, and a data processing system.

(2) The precision of the measurement is about 1/100 mm

and the time required for the measurement is about 120 seconds. The

system has already been placed in operation in a manufacturing plant.

4.6 Weight Density Sensor for Glass Wool Pipe

4.6.1 Introduction

The glass wool and fiber

have recently seen widespread applications. They are dust-proof papers in

semiconductor factories, separators to insulate electric current in batteries,

heat- and sound-resisting mats employed in automobiles and buildings. The

efficiency of the finished goods depends mainly on the uniformity of weight

density of raw glass wool when it is used in mats, fiber diameter when it is

used in filters, and thickness when it is used in pipes. We have developed an

optical system for monitoring the weight density of raw glass wool 18,19)

and the thickness of a semi-transparent foam sheet11,13) by passing

light through them. Further, we have developed a system for measuring the mean

diameter of optical fiber by reflected light20,21). A light

interacting with the measured object can be used directly in all these methods

since the objects are semi-transparent and roughly constitute a flat plane.

Another example of glass

wool application will be a pipe for protecting against heat and cold of a metal

pipe through which water, steam and other fluids flow. The deviation of the

pipe's thickness, i.e., an eccentricity, will be most important for a practical

use. The eccentricity has hitherto been measured by CCD camera. This method has

two distinct disadvantages. Firstly, it can only measure eccentricity at the

edge and not at the center region of the pipes. Secondly, measurement errors

are produced by a lack of clarity due to broken pieces of the glass wool. The

technique in this paper for measuring eccentricity of glass wool pipe is simple

and efficient, and further it does not possess the disadvantages inherent with

CCD camera method.

In this section, a

practical system for detecting the eccentricity of a glass wool pipe has been

developed optically by a hybrid method. The thickness of the pipe is measured

by the contact method and the displacement of a contact head is measured by an

optical method.

4.6.2 Principle and Method

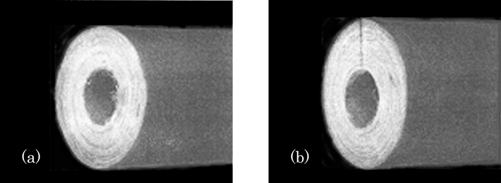

Figure 4.40 shows the

photographs of the glass wool pipe and Fig. 4.41 the schema of the pipe's cross

section. The pipe usually has an eccentricity, i.e., a deviation of the

thickness. This caused a serious problem at a junction when it was used to cover

the iron pipe in practice. An unacceptable pipe having too large an

eccentricity should then be rejected. The

eccentricity

of the glass wool pipe can, usually, be defined as,

|

|

(4.23) |

where

tmax is the maximum thickness of the glass wool pipe, tmin

the minimum thickness and ta the mean thickness, or defined

thickness. By the method described in this paper, the eccentricity can be

measured in all directions as the pipe rotates in a 360![]() arc, i.e., 1 cycle.

arc, i.e., 1 cycle.

Fig. 4.40 Photographs of physical glass wool pipe, (a)

without a cut, and (b) with a cut.

Fig. 4.41 Definition

of eccentricity.

The cross section of the

glass wool pipe was usually unclear due to the chips in cutting. Further, the

pipe itself was too soft for the thickness to be accurately measured. These

make the CCD camera method difficult. It is thus necessary to use the contact

method by loading a constant pressure on the surface for an accurate

measurement of the pipe's thickness. For this purpose we developed a hybrid

sensor system consisting of two sensor heads; a contact head and a light head.

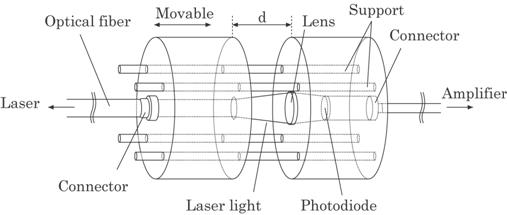

Figure 4.42 shows the

hybrid sensor system. Figure 4.42(a) shows a whole view of the system and Fig.

4.42(b) an enlarged view of the sensor. Both ends of the glass wool pipe are

held on the pipe support. The contact head with a rotator is placed on the pipe

as shown in Fig. 4.42 and imposes a constant pressure on the pipe, which

enables an accurate

Fig. 4.42

Schema of the hybrid sensor system consisting of two sensor heads; (a)

whole view of the sensor system, and (b) an enlarged view of the contact and

optical heads.

measurement.

The measurement can be done at any position in the axial direction of the pipe.

The CCD camera method can only measure the eccentricity of the cross section at

the end. As the pipe rotates, the contact head will be displaced up and down

according to the thickness of the glass wool pipe. A sheet-like laser light was

used to measure the displacement of the contact head. That is, the light sensor

can accurately detect the displacement since the light intensity is in

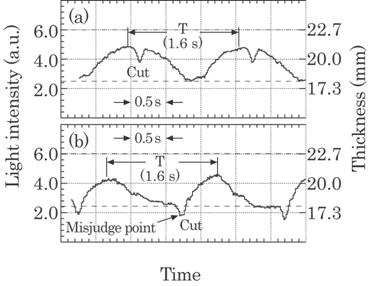

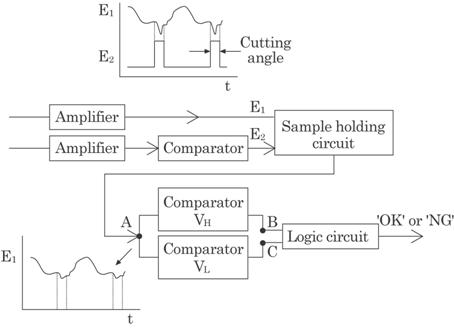

proportion to the pipe's thickness. The dusts on a laser and a photo receiver

cause a measurement error when the system is used in a practical plant. The problem